1. When you hit the punch, you do not want it to

slip sideways over your work.

2.

You do not want the hammer to slip off the

punch and strike your fingers. You can

eliminate both of these troubles by holding the

punch at right angles to the work and striking

the punch squarely with your hammer.

The center punch, as the name implies, is used for

marking the center of a hole to be drilled. If you try to

drill a hole without first punching the center, the drill

will "wander" or "walk away" from the desired center.

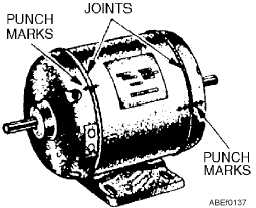

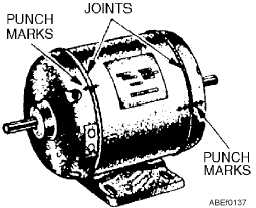

Another use of the center punch is to make

corresponding marks on two pieces of an assembly to

permit reassembling in the original positions. Before

taking a mechanism apart, make a pair of center

punchmarks in one or more places to help in

reassembly. To do this, select places, staggered as

shown in figure 1-51, where matching pieces are

joined. First, clean the places selected. Then, scribe a

line across the joint, and center punch the line on both

sides of the joint, with single and double marks as

shown to eliminate possible errors. In reassembly, refer

first to the sets of punchmarks to determine the

approximate position of the parts. Then line up the

scribed lines to determine the exact position.

To make the intersection of two layout lines, bring

the point of the prick punch to the exact point of

intersection and tap the punch lightly with a hammer. If

inspection shows that the exact intersection and the

punchmark do not coincide, as in view A of figure 1-52,

slant the punch as shown in view B and strike again

with the hammer, thus enlarging the punchmark and

centering it exactly. When the intersection has been

correctly punched, finish off with a light blow on the

punch held in an upright position. View C shows the

corrected punchmark.

DRIFT

punches,

sometimes

called

"starting

punches," have a long taper from the tip to the body.

They are made that way to withstand the shock of heavy

blows. They may be used for knocking out rivets after

the heads have been chiseled off or for freeing pins that

are "frozen" in their holes.

After a pin has been loosened or partially driven

out, the drift punch may be too large to finish the job.

The follow-up tool to use is the PIN PUNCH. It is

designed to follow through the hole without jamming.

Always use the largest drift or pin punch that will fit the

hole. These punches usually come in sets of three to

five assorted sizes. Both of these punches will have flat

ends, never edged or rounded.

To remove a bolt or pin that is extremely tight, start

with a drift punch that has an end diameter that is

slightly smaller than the diameter of the object you are

removing. As soon as the bolt or pin loosens, finish

driving it out with a pin punch. Never use a pin punch

for starting a pin, because it has a slim shank and a hard

blow may cause it to bend or break.

For assembling units of a machine, an ALIGN-

MENT (aligning) punch is invaluable. It is usually

about 1-foot long and has a long gradual taper. Its

purpose is to line up holes in mating parts.

Hollow metal-cutting punches are made from

hardened tool steel. They are made in various sizes and

are used to cut holes in light gauge sheet metal.

Other punches have been designed for special uses.

One of these is the soft-faced drift. It is made of brass or

fiber and is used for such jobs as removing shafts,

bearings, and wrist pins from engines. It is generally

heavy enough to resist damage to itself, but soft enough

not to injure the finished surface on the part that is being

driven.

1-33

Figure 1-51.—Punch marking mating parts.

Figure 1-52.—Marking the intersection of lines with a prick

punch.