grooves, a surface adapted to grasping cylindrical

objects.

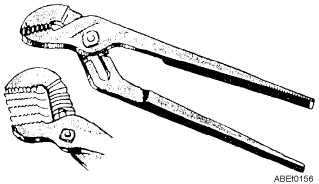

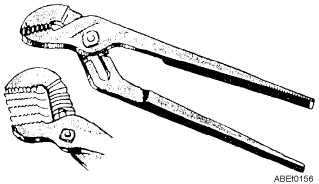

GROOVE-JOINT PLIERS

Groove-joint pliers (fig. 1-46) are another version

of water-pump pliers and are easily identified by the

extra-long handles, which make them a very powerful

gripping tool. They are shaped approximately the same

as the pliers just described, but the jaw opening

adjustment is effected differently. Groove-joint pliers

have grooves on one jaw and lands on the other. The

adjustment is effected by changing the position of the

grooves and lands. The groove-joint pliers are less

likely to slip from the adjustment setting when gripping

an object. The groove-joint pliers will only be used

where it is impossible to use a more adapted wrench or

holding device. Many nuts and bolts and surrounding

parts have been damaged by improper use of

groove-joint pliers.

DIAGONAL PLIERS

Diagonal cutting pliers (fig. 1-42) are used for

cutting small, light material, such as wire and cotter

pins in areas that are inaccessible to the larger cutting

tools. Also, since they are designed for cutting only,

larger objects can be cut than with the slip-joint pliers.

Because the cutting edges are diagonally offset

approximately 15 degrees, diagonal pliers are adapted

to cutting small objects flush with a surface. The inner

jaw surface is a diagonal straight cutting edge.

Diagonal pliers should never be used to hold objects,

because they exert a greater shearing force than other

types of pliers of a similar size. The sizes of the

diagonal cutting pliers are designated by the overall

length of the pliers.

SIDE-CUTTING PLIERS

Side-cutting pliers (sidecutters) are principally

used for holding, bending, and cutting thin materials or

small gauge wire. Sidecutters vary in size and are

designated by their overall length. The jaws are

hollowed out on one side just forward of the pivot point

of the pliers. Opposite the hollowed out portion of the

jaws are the cutting edges (fig. 1-42).

When holding or bending light metal surfaces, the

jaw tips are used to grasp the object. When holding

wire, grasp it as near one end as possible because the

jaws will mar the wire. To cut small-diameter wire, the

side-cutting edge of the jaws near the pivot is used.

Never use sidecutters to grasp large objects, tighten

nuts, or bend heavy gauge metal, since such operations

will spring the jaws.

Sidecutters are often called electrician or lineman

pliers.

They

are

used

extensively

for

stripping

insulation from wire and for twisting wire when

making a splice.

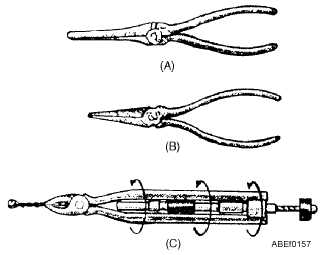

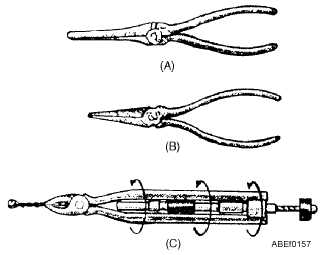

DUCKBILL PLIERS

Duckbill pliers (fig. 1-47, view A) have long wide

jaws and slender handles. Duckbills are used in

confined areas where the fingers cannot be used. The

jaw faces of the pliers are scored to aid in holding an

item securely. Duckbills are ideal for twisting the safety

wire used in securing nuts, bolts, and screws.

1-29

Figure 1-46.—Groove-joint pliers.

Figure 1-47.—Pliers; (A) duckbill, (B) needle-nose, and

(C) wire twister.