NEEDLE-NOSE PLIERS

Needle-nose pliers (fig. 1-47, view B) are used in

the same manner as duckbill pliers. However, there is a

difference in the design of the jaws. Needle-nose jaws

are tapered to a point, which makes them adapted to

installing and removing small cotter pins. They have

serrations at the nose end and a side cutter near the

throat. Needle-nose pliers may be used to hold small

items steady, to cut and bend safety wire, or to do

numerous other jobs that are too intricate or too difficult

to be done by hand alone.

NOTE

Duckbill

and

needle-nose

pliers

are

especially delicate. Care should be exercised

when using these pliers to prevent springing,

breaking, or chipping the jaws. Once these

pliers are damaged, they are practically

useless.

WIRE-TWISTER PLIERS

Wire-twister pliers (safety wire pliers) (fig. 1-47,

view C) are three-way pliers: they hold, twist, and cut.

They are designed to reduce the time used in twisting

safety wire on nuts and bolts. To operate, grasp the wire

between the two diagonal jaws, and the thumb will

bring the locking sleeve into place. A pull on the knob

twirls the twister, making uniform twists in the wire.

The spiral rod may be pushed back into the twister

without unlocking it, and another pull on the knob will

give a tighter twist to the wire. A squeeze on the handle

unlocks the twister, and the wire can be cut to the

desired length with the side cutter. The spiral of the

twister should be lubricated occasionally.

MAINTENANCE OF PLIERS

Nearly all sidecutting pliers and diagonals are

designed so that the cutting edges can be reground.

Some older models of pliers will not close if material is

ground from the cutting edges. When grinding the

cutting edges, never take any more material from the

jaws than is necessary to remove the nicks. Grind the

same amount of stock from both jaws.

NOTE

When jaws on pliers do not open enough to

permit grinding, remove the pin that attaches

the two halves of the pliers, so that the jaws can

be separated.

The serrations on the jaws of pliers must be sharp.

When they become dull, the pliers should be held in a

vise and the serrations recut by using a small

three-corner file.

Pliers should be coated with light oil when they are

not in use. They should be stored in a toolbox in such a

manner that the jaws cannot be injured by striking hard

objects. Keep the pin or bolt at the hinge just tight

enough to hold the two parts of the pliers in contact, and

always keep the pivot pin lubricated with a few drops of

light oil.

REVIEW QUESTIONS

Q14.

Identify the different types of pliers.

Q15.

What are wrench pliers used for?

Q16.

What are side-cutting pliers used for?

Q17.

What is used to sharpen the serrations on the

jaws of pliers?

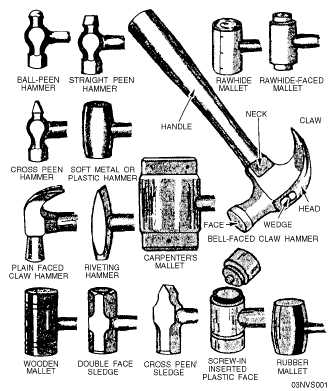

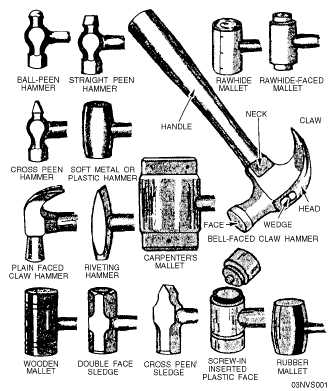

STRIKING TOOLS

LEARNING OBJECTIVES: Identify the

different types of striking tools. Describe the

uses of different types of striking tools.

Describe the proper care of striking tools. List

the safety precautions that apply to striking

tools.

Hammers, mallets, and sledges are used to apply a

striking force. The tool you select (fig. 1-48) will

depend upon the intended application.

1-30

Figure 1-48.—Hammers, mallets, and sledges.