The water brakes stop the forward motion of the shuttle

and pistons at the end of the catapult power stroke. The

after end of each water-brake cylinder is supported and

aligned by the most forward section of each launching

engine cylinder, which telescopes over the after end of

the water-brake cylinder. The forward end of each

cylinder is anchored in place by an upper bracket and

lower support saddle and chock.

The open end of each cylinder holds four rings.

They are the choke ring, the annulus ring, the jet ring,

and the striker ring.

The choke ring is the innermost ring and is threaded

into the water-brake cylinder. The annulus ring has

angled holes machined in it to direct pressurized water

into the cylinder and forms a vortex (whirlpool) at the

open end of the cylinder. The jet ring is bolted to the end

of the cylinder and holds the annulus ring in place. The

striker ring, the outermost of the four rings, are

designed to absorb the impact of any metal-to- contact

between the launching engine piston assemblies and

the aft end of the water brakes.

WARNING

To prevent damage to the water brakes and

piston assembly components, a water-brake

pump must be running any time the shuttle and

piston assemblies are not fully bottomed in the

water brakes.

A vane is keyed to the end plug (see fig. 4-27). Its

purpose is to break up the vortex caused by the annulus

ring and to create a solid head of water in the cylinder,

which is maintained by the continued vortex action at

the mouth of the cylinder.

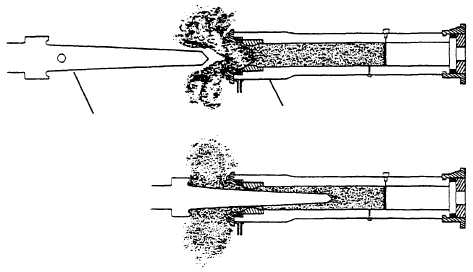

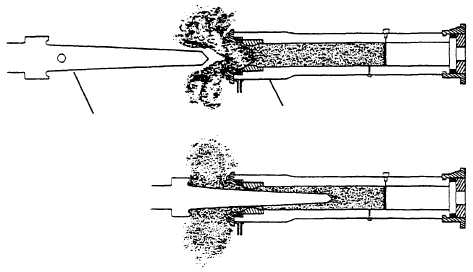

Braking action occurs at the end of the power run

when the tapered spear on the piston assembly enters

the water brake. Water in the brake is displaced by the

spear and forced out the after end of the cylinder

between the choke ring and the spear (fig. 4-28). Since

the spear is tapered, the space between the choke ring

and the spear is gradually decreased as the spear moves

into the brake cylinder. This arrangement provides a

controlled deceleration and energy absorption, which

stops the piston assembly within a distance of about 5

feet without damage to the ship's structure.

WATER-BRAKE TANK

The water-brake tank is installed below the

water-brake cylinders to supply water to and reclaim

water spillage from the water brakes during operation.

It has a minimum capacity of 3,000 gallons of fresh

water. Overflow and oil-skimming funnels and bottom

drains are provided in the tank to maintain proper water

level and to remove excess oil used in the lubrication of

the launching engine cylinders.

WATER-BRAKE PUMPS

Water is supplied to the water-brake cylinders by

two electric-motor-driven, rotary-vane-type pumps

installed in the immediate vicinity of the water-brake

tank. They are capable of producing 650 gallons of

water per minute at 80 psi. The pumps are electrically

interlocked so that if the running pump breaks down,

4-20

PISTON SPEAR

WATER BRAKE CYLINDER

ABEf0429

Figure 4-28.—Water brakes.