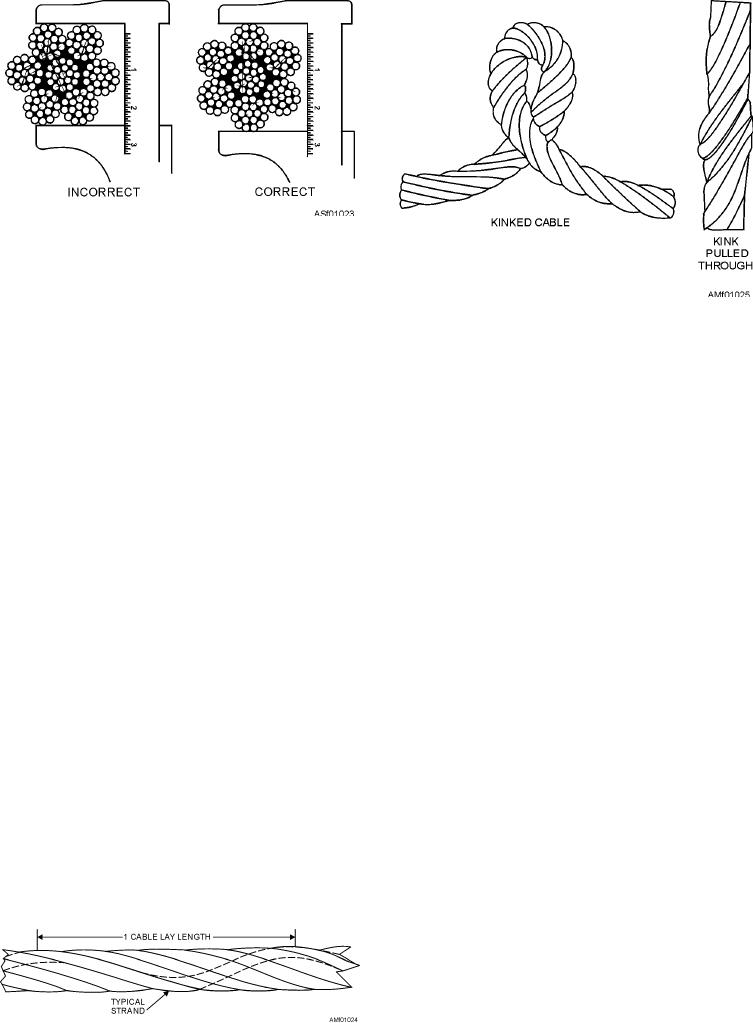

Figure 1-23.--Measuring the diameter of a wire rope.

cross section. Figure 1-23 shows the proper method of

measuring the diameter of a wire rope.

Figure 1-25.--Cable damage resulting from a pulled-through

2. Lay Length. The distance, parallel to the axis

kink.

of the cable, in which a strand makes one complete turn

STRUCTURAL STEEL OR ALUMINUM.--

about that axis is known as the lay length or pitch

Visually inspect all terminals, shackles, lugs, and struc-

length. Figure 1-24 shows the lay length of a wire rope.

tural members for misalignment, wear, corrosion, de-

Wire rope cables are visually inspected for knots,

formation, loosening, slippage, fractures, open welds,

fraying, stretching, abrasions, severe corrosion, and

pitting, and gouges. Examine slides and screw adjusters

other signs of failure. Of particular importance is the

for burrs, misalignment, and ease of operation. Inspect

detection of a cable in which a kink has been pulled

sling attachment bolts and pins for elongation, wear,

through in order to straighten the cable. The resultant

deformed threads, and other signs of imminent failure.

deformation is known as a bird cage. See figure 1-25. In

CHAINS.--Chains will be visually inspected for

such a case, the sling should be discarded.

stretched links, wear, gouges, open welds, fractures,

The presence of one or more broken wires in one

kinks, knots, and corrosion. Chain attachment fittings

rope lay length or one or more broken wires near an

and adjusters will be examined for security, wear,

attached fitting is cause for replacement. If a broken

corrosion and deformation.

wire is the result of corrosion or if the cable is

excessively corroded, the cable must not be used

Lubrication, Transportation, and Storage

regardless of the number of broken wires. Replace

Requirements

cables exhibiting rust and development of broken wires

in the vicinity of attached fittings. Replace wire ropes

Examine and lubricate all slings once a month in

evidencing bulges, core protrusions, or excessive

accordance with NAVAIR 17-1-114. When

reductions in rope diameter.

transporting slings, they will be carried at all times.

FABRIC OR WEBBING.--Fabric or webbing

Dragging slings over floors, runways, decks, and

straps must be visually inspected for cuts, holes, severe

obstructions can cut or severely abrade the material.

abrasions, mildew, dry rot, broken stitches, frays and

This malpractice results in an unserviceable sling.

deterioration. Deterioration may be caused by contact

Whenever possible, slings should be stored indoors in a

with foreign materials, such as oil, fuel, solvents,

clean, dry, well-ventilated area so as to be protected

caustic fluids, dirt, and lye. The existence of any of the

from moisture, salt atmosphere, and acids of all types.

above conditions renders the sling unserviceable.

In addition, slings constructed with nylon or other

Twists, knots, and similar distortions must be corrected

fabric materials will be stored in such a way as to

before use.

prevent contact with sharp objects, high temperatures,

and sunlight. Fabric materials deteriorate rapidly from

prolonged exposure to sunlight or excessive

heat--severely reducing strength and service life.

Where practicable, slings will be securely fastened to

overhead storage racks to prevent accidental damage.

Avoid laying slings on ash or concrete floors.

Figure 1-24.--Cable lay length.

1-28