excess of 10 percent over the rated capacity is applied.

Hoisting Restrictions

For example, the safety valve on a 10-ton jack will

There are many restrictions to hoisting for each

bypass fluid at 11 tons of pressure.

type of aircraft. Most hoisting restrictions are the same

Axle Jacks

as for jacking aircraft. If you violate any of these

restrictions, there is a good chance that you will have an

Use axle jacks for raising one main landing gear or

accident, damage the aircraft, or injure someone. The

the nose gear of an aircraft for maintenance of tires,

restrictions generally concern aircraft gross weight and

wheels, and struts. There are four different types of axle

configuration. Some of the considerations are access

jacks and many different sizes (lifting capacity in tons).

(stress) panels on or off, external stores on or off, and

The smaller hydraulic axle jacks are normally squadron

wings, folded or spread.

or unit permanent custody equipment. That means your

There are many factors that can affect the safety of

outfit is responsible for making sure the jacks are load

the aircraft and personnel during hoisting operation.

tested at the support equipment (SE) division of

For details on restrictions and for the proper installation

the Aircraft Intermediate Maintenance Department

of any sling, consult the applicable MIM. Don't forget

(AIMD) before being put into service, and annually

that many squadrons have their own local standing

thereafter. Special inspections include 13-week inspec-

instructions for hoisting aircraft that contain additional

tions at AIMD SE, but a load test is not required every

safety precautions and restrictions. You must know

13 weeks. A record of maintenance, inspections,

these precautions and restrictions as well.

technical directives, and load testing is kept on OPNAV

Prior to carrier operation, aircraft hoist points are

Form 4790/51.

inspected for serviceability and easy access in an emer-

All model designations for axle jacks begin with

gency. For details on how to accomplish this inspection

the letter A, for axle, such as A10-1HC. The number

on your aircraft, consult the applicable MIM.

following the A shows the jack capacity in tons, such as

Q1-34.

What are the four types of aircraft slings?

10 for a 10-ton jack. This is followed by a dash (-) and

Q1-35.

What is the most common type of aircraft

the specific jack identification number. Then comes

lifting sling used today?

two letters that show the type of jack (HC = hand

carried, HS = horseshoe, TB = T-bar, and OR =

Q1-36.

What types of slings do not contain flexible

outrigger). The four types of axle jacks are discussed in

components?

the following text.

Q1-37.

What manual covers load testing and

inspection information for aircraft slings?

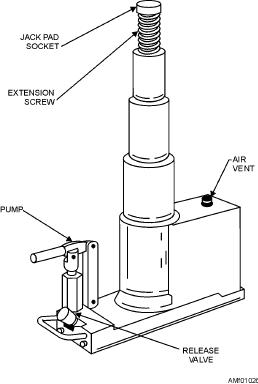

HAND CARRIED.--These axle jacks (fig. 1-26)

are portable, self-contained units, with single or double

Q1-38.

How often should inspection and lubrication

of aircraft slings be accomplished?

AIRCRAFT JACKING

LEARNING OBJECTIVE: Recognize the

procedures for the safe raising and lowering of

aircraft by the proper use of aircraft jacks.

Identify the various types of jacks presently

found in the naval inventory.

The following text will familiarize you with the

various types of jacks, their use, and general safety

procedures. You will become familiar with jack

identification, preoperational inspections, and jacking

procedures.

JACK IDENTIFICATION

All aircraft hydraulic jacks are either axle or

airframe (tripod) jacks. These jacks use standard,

authorized aircraft hydraulic fluid. They have a safety

bypass valve that prevents damage when a load in

Figure 1-26.--Hand carried axle jack.

1-29