and the sequence in which the different

and continuity checks will contribute significantly to

components operate?

efficient troubleshooting. If a malfunction is caused by

electrical problems, the assistance of AE personnel

Q1-13.

What type of diagram is a graphic

may be required.

representation of a system that shows how a

component fits with other components but

All electrical wiring in the aircraft is marked at

does not indicate its actual location in the

specified intervals with a wire identification code.

aircraft?

These identification codes are defined in the electrical

volume(s) of the MIM, and they are useful in tracing

Q1-14.

What type of diagrams use actual drawings of

wires throughout the aircraft. If an elusive malfunction

components within the system?

is reasonably traced to or considered to be of an elec-

trical nature, the electrical circuit should be checked by

TROUBLESHOOTING AIRCRAFT

a qualified AE. Many wires can give a good continuity

SYSTEMS

reading under a no-load or low-current condition and

still be malfunctioning when under a load condition.

LEARNING OBJECTIVE: Recognize the

definition of troubleshooting. Identify the

NOTE: Electrical schematics are especially useful

seven steps in the troubleshooting procedures.

in determining annunciator panel malfunctions.

Troubleshooting/trouble analysis may prove to be

Installation Diagrams

the most challenging part of system maintenance.

Troubleshooting is the logical or deductive reasoning

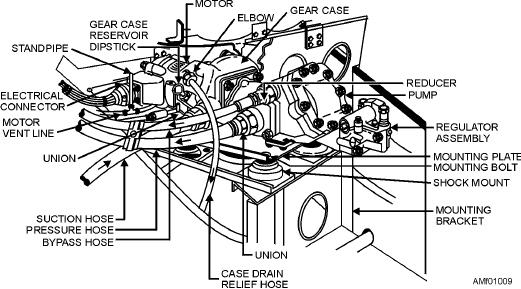

Figure 1-9 is an example of an installation diagram.

procedure used when you are determining what unit is

This is a diagram of the motor-driven hydraulic pump

causing a particular system malfunction. The MIM for

installation. Installation diagrams show general loca-

each aircraft generally provides troubleshooting aids

tion, function, and appearance of parts and assemblies.

that encompass the following seven steps:

On some installation diagrams, letters on the principal

1. Conduct a visual inspection

view refer to a detailed view located elsewhere on the

diagram. Each detailed view is an enlarged drawing of a

2. Conduct an operational check

portion of the system identifying each of the principal

3. Classify the trouble

components for purposes of clarification. Diagrams of

this type are invaluable to maintenance personnel in

4. Isolate the trouble

identifying and locating components. Installation

5. Locate the trouble

diagrams will aid you in understanding the principle of

operation of complicated systems.

6. Correct the trouble

Q1-12.

What type of diagram is useful for showing

7. Conduct a final operational check.

the relationship of components of a system

Figure 1-9.--Installation diagram of a motor-driven hydraulic pump.

1-11