Other MIMs use trouble analysis sheets to pursue a

Table 1-1 shows a representative troubleshooting

trouble to a satisfactory solution by the process of

table. The troubles in this table are numbered to

elimination. The symptom is defined in tabular form

correspond with the step of the operational check

with a remedy for each symptom. An example of

procedures where the trouble will become apparent.

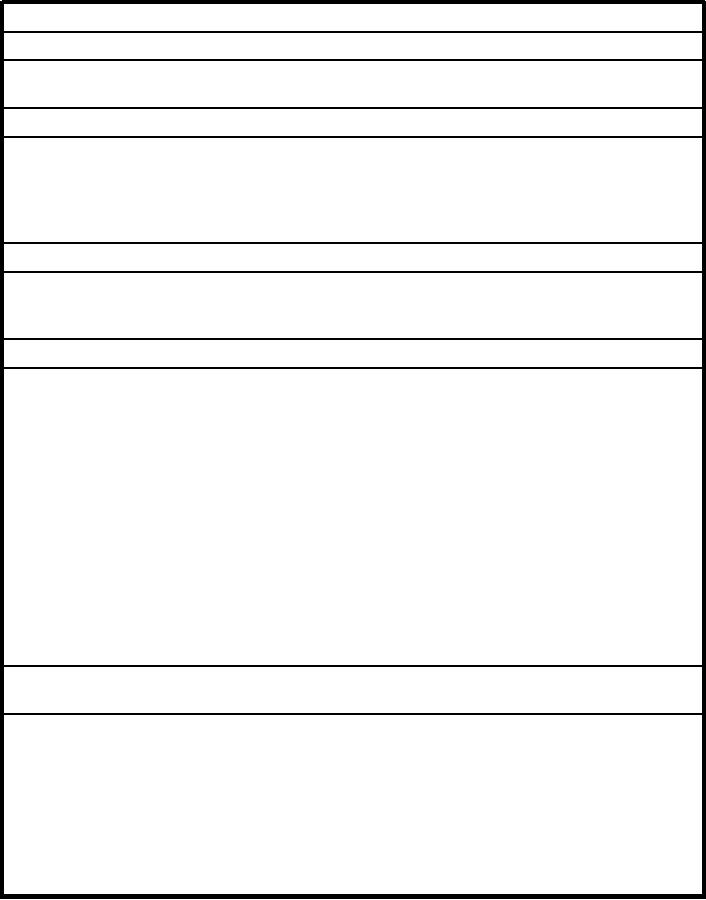

Table 1-1.--Troubleshooting Flight Hydraulic Power System

Probable Cause

Isolation Procedure

Remedy

STEP 1 TROUBLE:

RESERVOIR FLUID LEVEL INDICATOR INDICATES BELOW FULL

Reservoir fluid level low.

Check reservoir fluid level.

Service

hydraulic

system

reservoir.

STEP 2 TROUBLE:

FILTER DIFFERENTIAL PRESSURE INDICATOR BUTTON UP

Indicator button not properly

Manually reset indicator button.

Operate hydraulic power system.

reset.

If normal operation results, no

further action required. If

indicator button pops, clean

and/or replace filter element.

STEP 3 TROUBLE:

SYSTEM HYDRAULIC PRESSURE FAILS TO DEPLETE

Accumulator pressure gauge

Replace gauge with a known

If normal operation results after

defective.

operative gauge.

replacement, use replacement

gauge.

STEP 4 TROUBLE:

ACCUMULATOR PRESSURE GAUGE DOES NOT INDICATE 2,000 PSI

Improper accumulator preload.

Deplete hydraulic system pressure,

Service accumulator preload.

then check accumulator pressure

preload.

Air filler valve.

Check air filler valve for leakage.

Retorque swivel nut or replace

defective O-ring, defective filler

valve.

Pneumatic lines.

Check pneumatic lines for leakage.

Retorque or replace

faulty

pneumatic line section.

Accumulator pressure gauge.

Replace gauge with a known

If normal operation results after

operative gauge.

replacement, use replacement

gauge.

Accumulator.

Check accumulator for leakage.

Replace defective O-rings or

defective accumulator.

STEP 5 TROUBLE:

PILOT'S HYDRAULIC PRESSURE INDICATOR (UPPER LEFT DIAL)

INDICATES BELOW 3,000 PSI

Hydraulic lines.

Check hydraulic lines for leakage.

Retorque or replace

faulty

hydraulic line section.

Pilot's hydraulic pressure

Replace indicator with a known

If normal operation results after

indicator.

operative indicator. (Refer to

replacement, use replacement

NAVAIR 01-85ADA-2-5.)

indicator.

Pressure transmitter.

Replace transmitter with a known

If normal operation results after

operative transmitter. (Refer to

replacement, use replacement

NAVAIR 01-85ADA-2-5.)

transmitter.

1-12