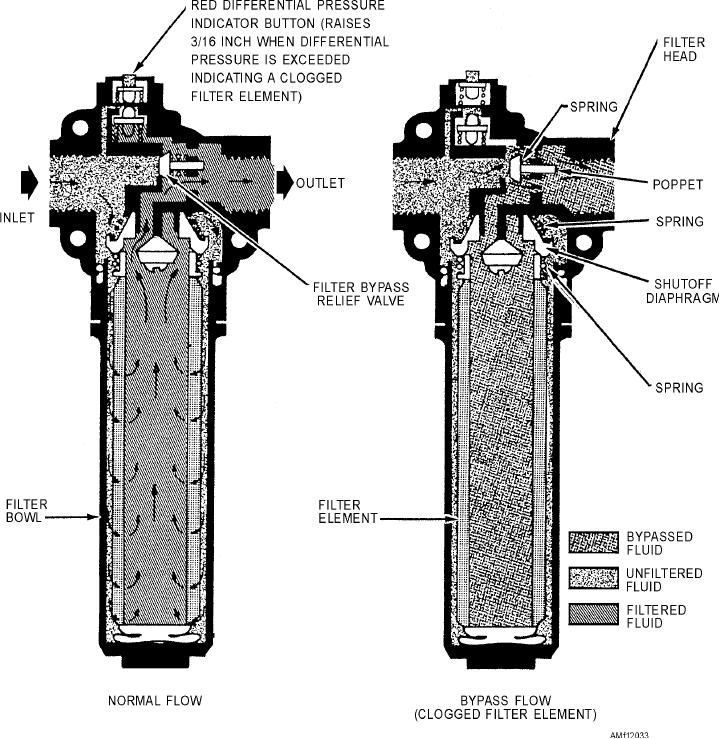

Figure 12-33.--Hydraulic filter assembly incorporating differential pressure indicator.

must be carefully handled to protect it from

visually inspected. An excessive amount of particulate

contamination and mechanical damage.

on its surface, as determined from experience, may be

indicative of upstream component failure and the need

5. The replacement element is installed in reverse

order of its removal. In most instances, the element is

for investigation. Check the solid end of filter element

inserted up into the head, employing a gentle twisting

for "Disposable" markings. If the filter element is

motion. O-ring seals located in the head, or sometimes

disposable, it should be discarded. If the filter element

in the element itself, prevent fluid from flowing around

is not disposable, it should be cleaned and handled

the element. It is important that these seals be inspected

carefully.

and replaced, if required, in accordance with the

applicable MIM.

4. The replacement filter element should not be

removed from its protective packing until just prior to

6. Prior to installation of the cleaned filter bowl,

installation. Once removed from packing, the element

the bowl is first filled with new filtered hydraulic fluid to

12-33