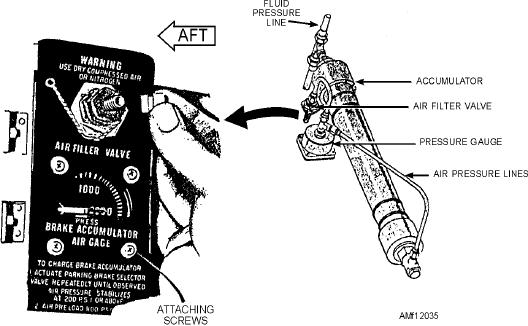

the brake system accumulator installation used on one

majority of the accumulators installed in naval aircraft

are equipped with air pressure gauges for this purpose.

type of aircraft. The air valve used in the accumulator

When the accumulator is not equipped with a

installations is usually the same type as that used on

high-pressure air gauge, you may install one at the air

shock struts.

preload fitting for this purpose. The required pressure

To service an accumulator, the hydraulic pressure

can be found in the MIM for each aircraft.

that is trapped in the accumulator must be relieved.

The preload pressure may be checked by another

This is accomplished by actuating the units involved.

method in case the accumulator is not equipped with an

For example, the hydraulic pressure in a brake

air pressure gauge. With the system pressure (as

a c c u m u l a t o r m a y b e r e l i eve d b y a p p l y i n g t h e

indicated by the cockpit gauge) at the normal operating

emergency brake several times. When the hydraulic

value, relieve system pressure by operating the wing

pressure is relieved, the accumulator gauge should

flaps or another unit slowly. The pressure gauge

indicate the air or nitrogen pressure specified for the

reading must be watched carefully. The last reading

particular accumulator installation. If the pressure

before the indicator needle drops suddenly to zero is

i n d i c a t e d i s b e l ow t h e s p e c i fi e d p r e s s u r e , t h e

accepted as the accumulator preload air pressure.

accumulator must be recharged with dry compressed

Before disassembly of any accumulator, ensure

air or nitrogen.

that the air preload has been completely exhausted.

This may be accomplished by loosening the swivel nut

PRESSURE INDICATORS

on the air filler valve until all air is out; then remove the

Pressure gauges installed in hydraulic and

valve.

pneumatic systems are used to indicate existing

Servicing

hydraulic and pneumatic pressures, and are calibrated

in pounds per square inch. Naval aircraft use both the

The purpose of the hydraulic system accumulator

direct reading gauges and the synchro (electric) type.

is to store an extra volume of fluid under pressure. The

energy stored in an accumulator is used for various

Direct Reading Type

purposes, such as the actuation of a unit in the event of

normal hydraulic system failure. For example,

Direct reading gauges are used in installations

sufficient energy can be stored in an accumulator for

such as accumulators, emergency air bottles, arresting

several applications of the wheel brakes.

gear snubbers, and brake systems. The gauge is

connected directly into units or lines leading from units

Most accumulators are installed with an air gauge

and become part of the container or system. At these

and a high-pressure air valve mounted on a panel of the

structure near the accumulator. Figure 12-35 shows

points, the gauge is able to sample existing pressure.

Figure 12-35.--Accumulator air charge valve and gauge installation.

12-36