operates a hydraulic pump. The turbine and pump

assembly is generally installed on the inner surface of a

door installed in the fuselage. The door is hinged,

allowing the assembly to be extended into the

slipstream by pulling a manual release in the cockpit.

Figure 12-41 shows a typical ram air unit. This type of

emergency system is intended for use only when

normal hydraulic pumps are completely inoperative.

Because of differences in system designs, aircraft

emergency system operating pressures will differ from

one aircraft to another. The ram air turbine system

shown in figure 12-41 provides a means for emergency

hydraulic and electrical power when the normal

aircraft hydraulic system has failed. The

turbine-driven hydraulic pump supplies fluid under

pressure to the primary flight controls as well as to an

emergency hydraulically driven alternator.

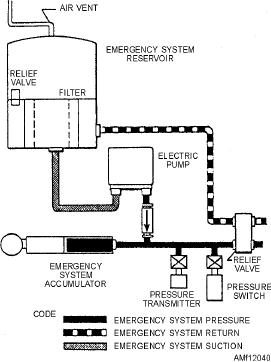

The turbine system shown in figure 12-42 consists

Figure 12-40.--Schematic diagram of typical emergency

of a dropout governor-controlled turbine, a hydraulic

power system (electric-motor driven).

pump connected in parallel to the normal hydraulic

system, a ram air turbine actuator, and a turbine-retract

accumulator, a relief valve, a pressure switch, a

control valve. You can pull the release handle, located

snubber, and a control switch in the cockpit.

in the cockpit within easy reach of the pilot, to operate

The main difference in a system of this type and a

the system. A mechanical latch releases the turbine

normal (engine-driven) system is that instead of

assembly into the airstream. The spring-loaded

operating continuously, the pump operates only when

turbine actuator initiates extension of the turbine

pressure is needed in the system. For example, if the

assembly, and the airstream force completes the

normal power system is inoperative, the pilot turns on

extension. During starting and acceleration of the

the emergency system switch in the cockpit. Turning

turbine, the turbine blades remain at a constant setting

this switch on energizes a pressure switch that is

until near maximum rpm. At this point, the governor

connected into the emergency hydraulic system

senses the shaft rpm and begins to vary the blade angle

pressure line. The pressure switch is actuated

to prevent excessive turbine speed. At this speed, the

automatically by hydraulic pressure.

pump is delivering its maximum amount of fluid. As

the turbine slows down, usually due to a decrease in

For example, when emergency system pressure

airspeed, the fluid delivery from the pump will also

drops below a predetermined point, the pressure switch

decrease. This type of system allows the aircraft to be

turns the pump motor on. When the pressure builds up

controlled in flight by supplying the necessary

to the designed operating psi, the pressure switch turns

hydraulic and electrical power.

the pump motor off.

The turbine is maintained in the fully extended

The system is protected from excessive pressures

position by a hydraulic lock in the turbine actuator.

by a relief valve, which is set to open at a pressure

When the RAM AIR TURBINE RETRACT button

slightly above system operating pressure. Emergency

switch is depressed, electrical power is supplied to the

power systems of this type are generally equipped with

solenoid-operated turbine retract control valve.

an accumulator for storing a reservoir supply of fluid

Hydraulic pressure from the hydraulic power system is

under pressure. This prevents the pump motor from

ported to the retract side of the turbine actuator (fig.

having to cut in repeatedly to maintain operating

12-42) through a restrictor, which controls the retract

pressure in the system.

speed. As the turbine door reaches the closed position,

the spring-loaded hook-type lock is cammed up until it

Ram Air Turbine-Driven System

drops over the roller, locking the door closed. When

In this type of emergency hydraulic system, ram

the button switch is released, electrical power is

removed from the control valve and the retract side of

air is used to turn the blades of a turbine that, in turn,

12-39