This initial charge is referred to as the accumulator

preload.

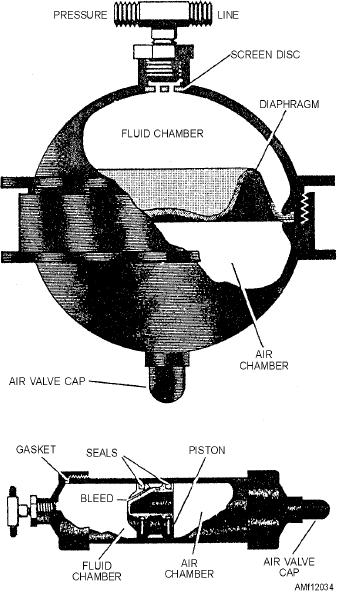

As an example of accumulator operation, let us

assume that the cylindrical accumulator in figure

12-34 is designed for a preload of 1,300 psi in a 3,000

psi system. When the initial charge of 1,300 psi is

introduced into the unit, hydraulic system pressure is

zero. As air pressure is applied through the air pressure

port, it moves the piston toward the opposite end until it

bottoms. If the air behind the piston has a pressure of

1,300 psi, the hydraulic system pump will have to

create a pressure within the system greater than 1,300

psi before the hydraulic fluid can actuate the piston.

Thus, at 1,301 psi the piston will start to move within

the cylinder, compressing the air as it moves. At 2,000

psi it will have backed up several inches. At 3,000 psi

the piston will have backed up to its normal operating

position, compressing the air until it occupies a space

less than one-half the length of the cylinder.

When actuation of hydraulic units lowers the

system pressure, the compressed air will expand

against the piston, forcing fluid from the accumulator.

This supplies an instantaneous supply of fluid to the

hydraulic system.

Many aircraft have several accumulators in the

hydraulic system. There may be a main system

accumulator and an emergency system accumulator.

There may also be auxiliary accumulators located in

various unit systems. Regardless of the number and

Figure 12-34.--Pressure accumulator, spherical and

their location within the system, all accumulators

cylindrical types.

perform the same function--that of storing an extra

volume of hydraulic fluid under pressure.

Cylindrical Type

Maintenance

Cylindrical accumulators consist of a cylinder and

Accumulators should be visually examined for

piston assembly. End caps are attached to both ends of

indications of external hydraulic fluid leaks. They

the cylinder. The internal piston separates the fluid and

should then be examined for external air leaks by

air/nitrogen chambers. Both the end caps and piston

brushing the exterior with soapy water, which will

are sealed with gaskets and packings to prevent

form bubbles where the air leaks occur.

external leakage around the end caps and internal

leakage between the chambers. In one end cap, a

The air valve assembly should be loosened to

hydraulic fitting is used to attach the fluid chamber to

examine the accumulator for internal leaks. If

the hydraulic system. In the other end cap, an air filler

hydraulic fluid comes out of the air valve, the

valve is installed to perform the same function as the

accumulator should be removed and replaced. The

filler valve installed in the spherical accumulator.

overhaul or repair of the accumulator is not a line

maintenance function, but it is the responsibility of an

Operation

intermediate-level activity.

The air preload pressure should be checked after

In operation, the compressed-air chamber is

relieving the hydraulic system pressure by operating

charged to a predetermined pressure, which is

the wing flaps or other hydraulically actuated unit. The

somewhat lower than the system operating pressure.

12-35