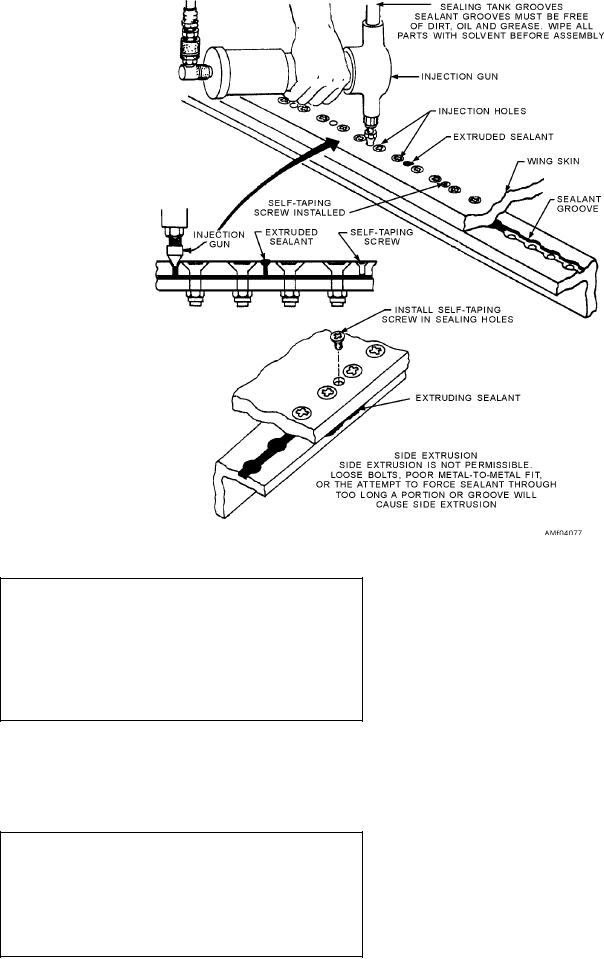

Figure 4-77.--Injection of sealing compound.

the tank must be heated above 70F before sealing is

attempted. This may be accomplished in a heated

CAUTION

hangar or by using portable heating units or electric

Do not use toluene for cleaning any surface with

blankets.

a corrosion-resistant or fuel-resistant coating.

NOTE: If the sealing compound does not appear

Toluene will remove the coating and cause the loss of

after approximately 4 to 5 minutes, you may assume

the coating's protective properties.

that the compound is too cold, the groove is plugged, or

the surface gap is excessive. In this case, the injection

should be discontinued until the discrepancy is

If the sealant is exceptionally slow to inject, the

tank may be heated to 110F. Heating can be

remedied.

accomplished by using electric blankets.

Testing

When an integral fuel cell has been repaired, it

CAUTION

must be pressure checked before it is filled with fuel.

Since the pressure testing procedure will vary with

Do not heat the tank in excess of 110F to seal the

different types of aircraft, you should always consult

injection groove as higher temperatures are con-

the structural repair manual for the aircraft concerned

sidered as a fire hazard.

for the proper procedure. The following equipment is

used for pressure testing a system:

The proper temperatures for sealing are 79 to

A source of nitrogen and a means of regulating

84F. If the tank is exposed to temperatures below 50F,

the nitrogen pressure

4-51