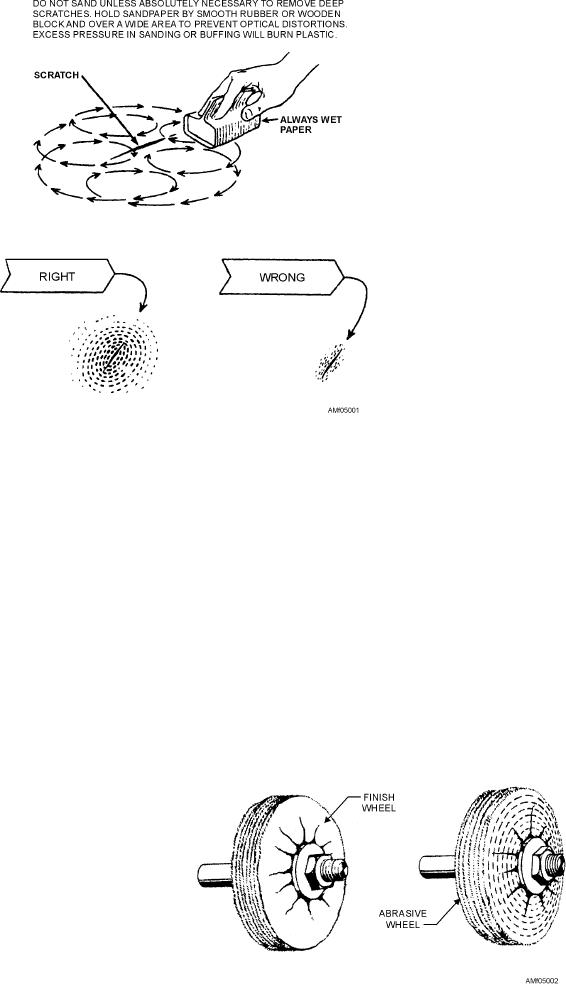

Figure 5-1.--Proper method of sanding plastic.

Plain tallow is often applied to the buffing wheel. It

Normally, you will never need abrasive paper

may be used in addition to buffing compound, or it may

coarser than No. 320A; however, abrasive paper as

be used alone. In the latter case, tallow functions

coarse as No. 240A may be used if the situation

similar to wax as it fills in hairline scratches and gives a

warrants. The abrasive paper is wrapped around a

high gloss to the surface.

felt-covered, wooden or rubber block, and the defective

area is rubbed lightly, using plain water or water with a

Buffing wheels are made of cotton cloth or felt. For

2-percent soap content as a lubricant. Use circular

removing scratches caused by sanding, an "abrasive"

strokes, as shown in figure 5-1. Never use a straight

wheel and a "finish" wheel are needed (fig. 5-2). The

back-and-forth motion. Sand an area about two or three

abrasive wheel, which is relatively hard and to which

times the length of the defect in order to minimize

buffing compound is applied, is used for removing the

optical distortion and excessive thinning of the plastic.

deeper scratches. The finish wheel, which is soft, is

The initial sanding should then be followed by similar

then used to bring the plastic to a high polish. Both

treatments, using successively finer grades of

wheels are made up of numerous layers of cloth discs,

sandpaper in the following sequence: Nos. 400A,

but the abrasive wheel is made hard by several rows of

500A, and 600A. Wash the plastic after each operation.

During each step, the deeper scratches lefty the

preceding grade of abrasive should be removed.

BUFFING.--To remove the fine, hairline

scratches caused by sanding, transparent plastic may be

buffed. It is often possible to remove scratches by

buffing alone, provided the scratches are not too deep.

There are a number of standard commercial buffing

compounds satisfactory for use on transparent plastic

enclosures. They are usually composed of very fine

alumina or similar abrasive in combination with wax,

tallow, or grease binders. They are available in the form

of bars or tubes for convenience in applying to the

buffing wheel.

Figure 5-2.--Buffing wheels.

5-3