screws are not torqued correctly, the plastic panel may

fail while the aircraft is undergoing normal taxiing and

flight operations.

When you remove a plastic panel, there may be

several different lengths of screws to be removed. You

will save a lot of time by acquiring the habit of keeping

screws separated. An easy way to do this is to draw a

diagram of the panel on cardboard. Puncture each

screw hole, with an awl, through the cardboard. As each

screw is removed from the panel, it is installed in its

respective position on the cardboard. This is done with

each screw as it is removed.

During installation of the panel, remove each screw

from the cardboard and reinstall it in the same hole

from which it was removed until all of the screws are

reinstalled. If any screws or other fasteners are

damaged during removal or reinstallation, the part

replaced must be the same part number as the damaged

part. Some fasteners are required to be of nonmagnetic

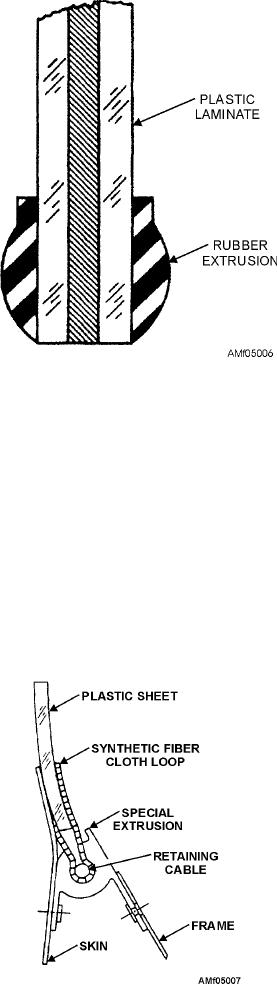

Figure 5-6.--Typical sighting dome attachment.

material because of their location near compasses and

other instruments. The specific part number for each

Since plastic expands and contracts three times as

fastener can be found in the Illustrated Parts

much as metal, suitable allowances for dimensional

Breakdown (IPB) for the aircraft.

changes with temperature must be made. Minimum

clearances between the frame and plastic are listed in

Q5-1. What are cracks and small surface fissures in

Fabrication, Maintenance and Repair of Transparent

transparent plastic materials called?

Plastics, NAVAIR 01-1A-12, or the applicable MIM.

Q5-2. What should you use to clean excessive

Clearances should be equally divided on all sides.

masking paper adhesive residue from plastic?

Screw torquing procedures should be in

Q5-3. What is normally used to measure scratches

accordance with the applicable MIM. Plastic panels

on plastic materials?

should not be installed under unnatural stresses. Each

screw must be torqued, as specified in the MIM, to

Q5-4. To sand out scratches in transparent plastic,

enable it to carry its portion of the load. If a plastic

what is the maximum coarse number of

panel is installed in a binding or twisted position and

abrasive paper that you may use?

Q5-5. What substance is often applied to the buffing

wheel in place of, or in addition to, a buffing

compound that acts similar to wax to fill

hairline scratches and provides a high gloss

to plastic surfaces?

Q5-6. How many times greater will plastics expand

and contract as compared to metal?

REPAIRING REINFORCED PLASTIC

This section covers the materials and procedures to

be used in repairing reinforced plastic and sandwich

construction components. The procedures discussed

are general in nature. When actually repairing

reinforced plastic and/or sandwich construction

components, refer to the applicable maintenance

instruction manual or structural repair manual.

Figure 5-7.--Typical loop edge attachment.

5-5