rubber, self-sealing cells, or bladder-type cells that fit

Q4-46.

What can you use to maintain aerodynamic

into cavities in the wing or fuselage of the aircraft.

smoothness when repairing negligible

damage, steps, and gaps?

Fuel tanks must have facilities for the inspection

and repair of the tank. This requirement is met by

Q4-47.

What step must you take before applying a lap

installing access panels in the fuselage and wings. Fuel

patch over a crack?

tanks must be equipped with sump and drains to collect

Q4-48.

As a general rule, when you make a flush

sediment and water. The construction of the tank must

patch, what is the maximum clearance

be such that any hazardous quantity of water in the tank

between the skin and the filler?

will drain to the sump, so the water can be drained from

Q4-49.

When making a repair over an internal

the fuel tank.

structure, what rivet pattern must you use?

Self-Sealing Fuel Cells

Q4-50.

The main spanwise members designed

primarily to take bending loads on the wing

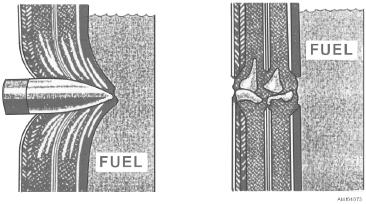

A self-sealing cell is a fuel container that

or other airfoils are known as what type of

automatically seals small holes or damage caused

members?

during combat operations. A self-sealing cell is not

bulletproof, merely puncture sealing. As shown in

Q4-51.

What structural members are designed to give

figure 4-73, the bullet penetrates the outside wall of the

the airfoil shape and rigidity?

cell, and the sticky, elastic sealing material surrounds

Q4-52.

What structural member runs fore-and-aft

the bullet. As the bullet passes through the cell wall into

along the length of the fuselage and is

the cell, the sealant springs together quickly and closes

continuous across frames and bulkheads?

the hole. Now some of the fuel in the tank comes in

contact with the sealant and makes it swell, completing

AIRFRAME FUEL SYSTEM

the seal. In this application, the natural stickiness of

rubber and the basic qualities of rubber and petroleum

LEARNING OBJECTIVE: Recognize the

seal the hole. This sealing action reduces the fire hazard

different types of aircraft fuel cells. Identify

brought about by leaking fuel. It keeps the aircraft's fuel

repair procedures for integral fuel cells.

intact so the aircraft may continue operating and return

Airframe fuel system maintenance is the

to its base.

responsibility of more than one work center. For

The most commonly used types of self-sealing fuel

instance, ADs remove and install bladder and

cells are the standard construction type and the type that

self-sealing fuel cells. Personnel of the AM rating

uses a bladder along with the self-sealing cell. Of the

perform the repairs on integral tanks. Personnel from

two, the standard construction cell is used the most. It is

the AO rating usually help in the installation and

a semiflexible cell, made up of numerous plies of

removal of external tanks (drop tanks).

material.

To meet the particular needs of the various types of

aircraft, fuel tanks vary in size, shape, construction, and

location. Sometimes a fuel tank is an integral part of a

wing. Most often fuel tanks are separate units,

configured to the aircraft design and mission.

FUEL TANK CONSTRUCTION

The material selected for the construction of a

particular fuel tank depends upon the type of aircraft

and its mission. Fuel tanks and the fuel system in

general are made of materials that will not react

chemically with any fuels. Fuel tanks that are an

integral part of the wing are of the same material as the

wing. The tank's seams are sealed with fuelproof

Figure 4-73.--Bullet-sealing action.

sealing compound. Other fuel tanks may be synthetic

4-46