you place the new sheet on the framework to drill the

The rivet holes in stringers, longerons, bulkheads,

holes, make certain that the reinforcing members are

formers, frames, rings, and other internal members

aligned and flush at the points at which they intersect;

must be kept in the best condition possible. If any of

otherwise, the holes in the new sheets will not be

these members are loosened by the removal of rivets,

accurately aligned. For the same reason, the new sheet

their location should be marked so they can be returned

should have the same contour as the old before drilling

to their original position.

the rivet holes.

You should refer to the applicable repair material

To duplicate holes from reinforcing members to the

chart in the aircraft structural repair manual for the

skin, you must exercise extreme care or both frame and

gauge and alloy of material to be used for the

skin will be ruined. Since most bulkheads, ribs, and

replacement panel. The size and shape of the panel may

stringers depend on the skin for some of their rigidity,

be determined in either of two ways. The dimensions

they can easily be forced out of alignment in the drilling

can be measured during the inspection, or the old skin

process. The skin must be held firmly against the

can be used as a template for the layout of the sheet and

framework, or the pressure from the drilling will force

the location of the holes. The second method is

it away from the frame and cause the holes to be out of

preferable and more accurate. Regardless of the method

alignment. This may be overcome by placing a block of

used, the new sheet must be large enough to replace the

wood against the skin and holding it firmly while the

damaged area, and it may be cut with an allowance of 1

drilling progresses. Also, make sure that the drill is held

to 2 inches of material outside the rivet holes.

at a 90-degree angle to the skin at all times, or the holes

If the old sheet is not too badly damaged, it should

will be elongated and out of alignment. When you drill

be flattened and used as a template. The new sheet,

through anchor nuts, a smaller pilot drill should be used

having been cut approximately 1 inch larger than the

first. You must use care so as not to damage the anchor

old, should then be drilled near the center of the sheet

nut threads. The pilot holes are then enlarged to the

by using the holes in the old sheet as a guide. The two

proper size.

sheets are then fastened together with sheet metal

It may be necessary to use an angle attachment or

fasteners. The use of sheet metal screws is not

flexible shaft drill in places where it is impossible to

recommended since they injure the edge of the rivet

insert a straight drill. In case neither type can be

holes. The drilling should proceed from the center to

inserted, the new section should be marked carefully

the outside of the sheet. You should insert sheet metal

with a soft pencil through the holes in the old section.

fasteners at frequent intervals.

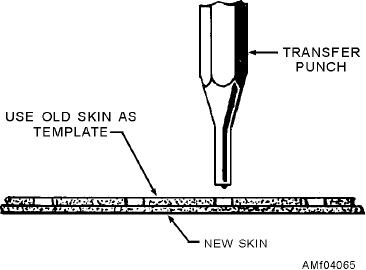

Another method of marking the location of the new

If it is impossible to use the old sheet as a template,

holes is to use a transfer or prick punch, as shown in

the holes in the new sheet should be drilled from the

figure 4-65. Center the punch in the old hole, and then

inside of the structure. Use the holes in the reinforcing

tap the punch lightly with a hammer. The result should

members as guides, and insert fasteners at frequent

be a mark that will serve to locate the hole in the new

intervals. This process is called backdrilling. Before

sheet.

Figure 4-65.--Transferring rivet holes.

4-41