When you are laying out the size of the doubler, the

trim a hole to a rectangular or elliptical shape and round

length should exceed the width. This enables the

the corners to a generous radius. See figure 4-61.

doubler to be slipped in through the skin and positioned

On larger repair areas, it is usually possible to buck

for installation. This eliminates the splitting and

the doubler rivets by inserting and holding the bucking

manipulation of the patch required in installing

bar through the center of the doubler. The filler is then

doublers of square and round flush patch repairs.

riveted in place with blind fasteners. When blind rivets

The filler is fabricated slightly less than the

are used as substitutes for solid rivets, the structural

dimensions of the hole being repaired. Generally, the

repair manual normally specifies the next larger size.

maximum clearance between the skin and the filler is

The proper edge distances for the substitute fasteners

one thirty-second of an inch. This will allow a

must be maintained.

1/64-inch clearance on each end of the filler and

NOTE: Edge distance was discussed earlier. In all

eliminate any possibility of stress developing from

flush patches, the filler should be of the same gauge and

contact between the two parts.

material as the original skin. The doubler, generally,

The doubler is fabricated larger than the hole being

should be of the same material and one gauge heavier

repaired to allow for the specified number of rivets

than the skin. Structural repair manuals will specify the

required to attach the doubler to the skin being repaired.

allowable substitution of materials. This can be in the

The doubler, filler, and attaching skin rivet pattern may

form of a Note on the repair diagram.

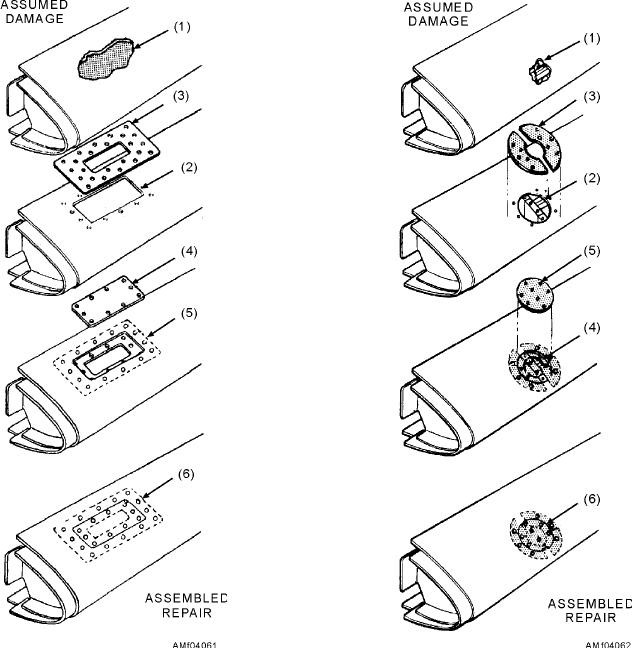

Figure 4-61.--Flush rectangular patch.

Figure 4-62.--Flush patch over internal structure.

4-38