especially true where there is an access door or plate

minimum number of rivet holes in the patch; normally

through which the rivets can be bucked. In inaccessible

four will suffice at an angle of 90 degrees to each other.

areas, the flush patch may be made by substituting

Position the patch over the surface being repaired, and

blind rivets for standard rivets, where permissible, and

ensure that the correct edge distances are being

devising a means of inserting the doubler through the

maintained. Drill four holes in the surface being

opening.

repaired, using the predrilled holes in the patch as a

pattern for alignment. As each hole is drilled, using the

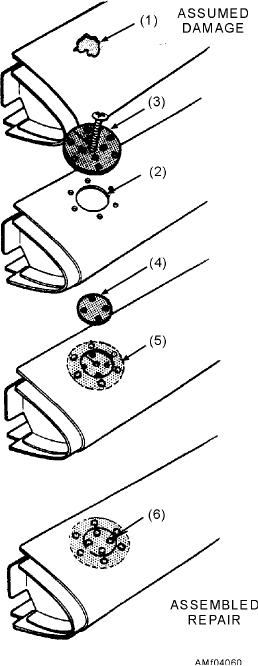

One method, shown in figure 4-60, has a doubler

proper temporary fasteners, secure the patch in place.

that has been split. To insert the doubler, slip the split

When the patch is temporarily secured, drill the

edge under the skin and twist the doubler until it slides

remaining rivet holes through the patch and the surface

in place under the skin. The screw in the center of the

being repaired. Remove the patch and deburr all rivets

doubler is temporarily installed to serve as a handle for

holes with a deburring tool or a large drill bit. Prime the

inserting the doubler through the hole. This type of

repair materials with the proper corrosion-preventive

patch is normally recommended for holes up to 1 1/2

material before the riveting operation. Secure the patch

inches in diameter. In holes larger than 1 1/2 inches,

in position with temporary fasteners to maintain

alignment during riveting.

Holes may be repaired in either stressed or

nonstressed skin that is less than three-sixteenths of an

inch in diameter by filling with a rivet. Drill the hole

and install the proper size rivet to fill the hole. For holes

three-sixteenths of an inch and larger, you should

consult the applicable structural repair manual for the

necessary repair information. The damaged area is

removed by cutting and trimming the hole to a circular,

square, rectangular, or diamond shape. The corners of

the hole should be rounded to a minimum of one-fourth

of an inch in radius. The lap patch is fabricated and

installed in the same manner as previously explained

for repairing cracks.

Flush Patches

A flush patch consists of a filler patch that is flush

with the skin after it is inserted. It is backed up and

riveted to a reinforcement plate that, in turn, is riveted

to the inside of the skin. This reinforcement plate is

usually referred to on some repair diagrams as

the doubler or the backup plate. On some

high-performance aircraft, only the flush patch is

permitted in making skin repairs.

Flush patches should be used where aerodynamic

smoothness is required. The type of flush patch used

depends on the location of the damaged area. One type

is clear of internal structures, and the other is not. Like

all types of repairs, you must consult the applicable

structural repair manual for the necessary repair

information. The repairs discussed next are typical of

most repairs.

FLUSH PATCH CLEAR OF INTERNAL

STRUCTURES.--In areas that are clear of internal

Figure 4-60.--Repair of small holes in skin with flush patch.

structure, the repair is relatively simple to make. This is

4-37