structure's rivet holes should be used when the rivet

be laid out, drilled, and deburred in the identical

pattern is laid out. The flush patch over internal

manner as described for a lap patch. After the required

structure is installed with the same methods as

corrosion-preventive materials have been applied, the

described for a flush patch clear of internal structure,

doubler is positioned in the structure's interior and

except for modification of the doubler.

secured with temporary fasteners. Inspect the rivet

holes for proper alignment, and rivet the doubler in

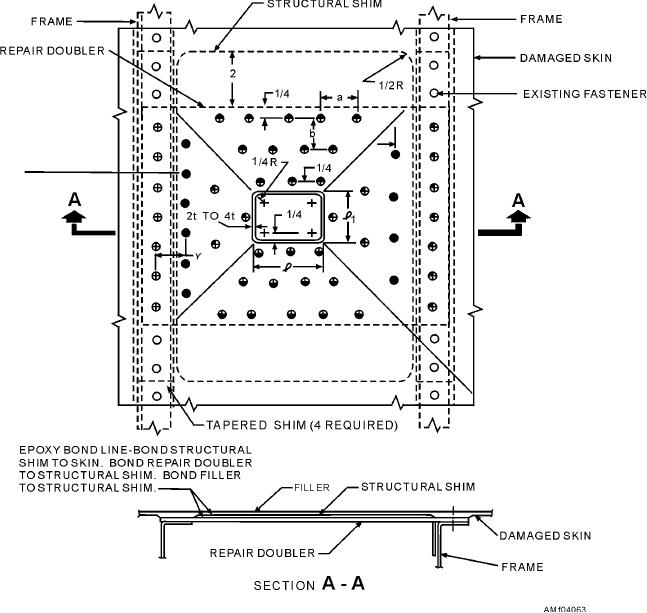

CHEM-MILLED SKIN REPAIR.--On some

place with solid rivets. The filler can then be riveted in

aircraft the fuselage skin is Chem-Milled or machine

place with blind fasteners.

tapered and highly stressed. Figure 4-63 shows a

Chem-Milled skin repair in a pressurized fuselage

NOTE: If the flush repair is in an open skin area,

section. The skin consists of a shim, a doubler, and a

the filler may be riveted to the doubler prior to installing

filler. The damage area is trimmed and the inside

the doubler.

corners are filed to one-fourth of an inch in radius. The

FLUSH PATCH OVER INTERNAL STRUC-

replaced metal and rivets or other fasteners must be

TURES.--Fabricating a flush patch over internal

equal to or stronger than the original. The structural

structures may become difficult. In some instances, it

repair manual should be consulted for fastener spacing,

may be done simply with a split doubler and a filler, as

edge distance, and repair procedure. During final

shown in figure 4-62. Frequently a split doubler, filler

assembly of the repair, the fabricated parts should be

strips, and filler are used in the repair. The filler strip is

bonded together with an adhesive to ensure

used as a spacer if a structural component under the

pressurization is maintained.

skin has been damaged. In all cases, the existing

Figure 4-63.--Chem-Milled skin repair (fuselage pressurized).

4-39