lications, materials, tools and equipment, and repair

Class V

Damage is single skin damage, includ-

procedures.

ing full penetration, accompanied with

honeycomb core damage.

The repair facilities where the work is to be

performed will be clean and climate controlled if

Class VI

Damage to both skins, including full

possible. The relative humidity should be 25 percent to

penetration, accompanied with honey-

60 percent and temperatures stable at 65F to 75F. If

comb core damage.

repairs are to be made in an uncontrolled environment

Class VII

Damage is water trapped in honeycomb

(hangar/flight deck), patches and adhesives will be

area.

prepared in a controlled environment and sealed in an

airtight bag before being brought to the repair site.

REPAIR CRITERIA

Strength Restoration

Repair criteria differ in the same way that initial

design requirements for aircraft differ. Criteria for a

Full strength repairs are desirable and should be

repair can be less demanding if the repair is considered

made unless the cost is prohibitive or the facilities are

temporary. Temporary repairs are performed for such

inadequate. Less than full strength repairs are

requirements as a onetime flight to a repair facility or

sometimes allowed on secondary structures that are

one more mission under combat conditions. However,

lightly loaded, stiffness-critical structures designed for

most repairs are intended to be permanent, and, except

limited deflections rather than for carrying large loads

for special conditions, criteria are applied so that the

(doors), or structures designed to a minimum thickness

repair will remain acceptable for the life of the aircraft.

requirement for general resistance to handling damage

(fuselage skins). Repair manuals for specific aircraft

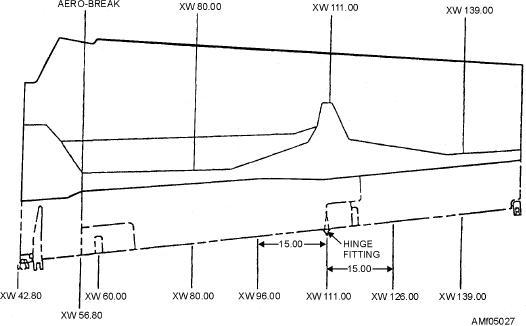

One of the major factors that influence the repair

frequently "zone" the structure to show the amount of

quality is the environment where the repairs are to

strength restoration needed or the kinds of standard

made. For example, the presence of moisture is critical

repairs that are acceptable. Repair zones help to

to bonded repairs. Epoxy resins can absorb 1.5 to 2

identify and classify damage by limiting repairs to the

times their weight in moisture, thereby reducing the

load-carrying requirements. Repair zone borders

ability of the resins to support the fibers. Dirt and dust

indicate changes in load-carrying requirements due to

can seriously affect bonded repairs. Oils, vapors, and

changes in the structure, skin thickness, ply drop-offs,

solvents prevent good adhesion in bonded surfaces and

location of supporting members (ribs and spars), ply

can lead to voids or delaminations. To perform quality

orientation, core density, size and type of materials.

repairs, personnel must have a knowledge of the

Damage in one zone may be repairable, where as the

composite system to be repaired, type of damage,

same type of damage in an adjacent zone may not be

damage limitations/ classifications, repair pub-

repairable. See figure 5-27.

Figure 5-27.--Repair zones.

5-22