CATEGORIES OF COMPOSITE MATERIAL

DAMAGE

Advanced composite materials continue to be

increasingly popular with designers of new aircraft. It is

estimated that new airframes will be 75 percent to 80

percent composites. As a structural mechanic, you will

be required to maintain these new types of aircraft. To

be proficient, you must be able to recognize the types of

damage, understand the processes involved in damage

assessment, inspection, and repair of composite

materials. As new materials are introduced, new repair

procedures will be required. It will be your

responsibility to keep abreast of these developments.

Composite materials damage may be categorized

as either environmental or physical. Environmental

damage includes crazing and cracking caused by solar

and ultraviolet radiation, water absorbed through

humidity and rain, and lightning strike damage.

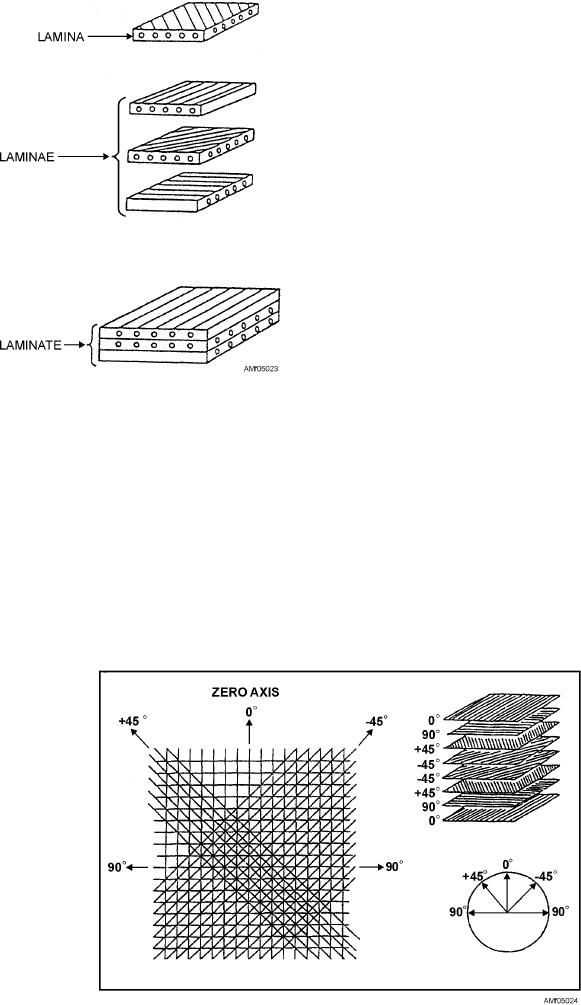

Figure 5-23.--Laminae stacking.

Lightning strikes can cause holes to be burned in the

structure, puncturing and splintering, and it has been

denoted in brackets, with the angle of each ply

known to weld bearings and hinges. Physical damage is

separated by a slash (/); for example,

caused by an applied force or deficiency in fabrication,

[+45/-45/+45/-45].

such as dents, scratches, cracks, cuts and abrasions,

Laminae are listed in sequence from the first

pits, voids, disbonds, delaminations, core crush on

lamina to the last. The brackets or parenthesis indicate

sandwich structures, and impact damage.

the beginning and the end of a code. The plus (+) and

ASSESSMENT OF COMPOSITE MATERIAL

minus (-) angles are relative to the "X" axis. Plus (+)

DAMAGE

signs are to the left of 0, and minus (-) signs are to the

right of 0. Adjacent laminae of equal angles but

The task of repair begins when you determined that

opposite signs are identified as , (45 = +45, -45). The

the structure has been damaged and that the damage is

directional strengths and stiffness of the laminate can

sufficient to require the structure to be repaired. The

be altered by changing the ply orientation.

Figure 5-24.--Standard ply orientation clock.

5-19