shape of the edge by tying the ends of a rib section

together and joining the upper and lower skins. These

trailing edges are very easily damaged. The majority of

this type of damage can be avoided if care is taken when

moving aircraft in confined spaces, and/or when

positioning ground support equipment around parked

aircraft. The trailing edges on some high-performance

aircraft are almost knife-edge in construction. You must

take extreme care when working around these surfaces

to avoid injury.

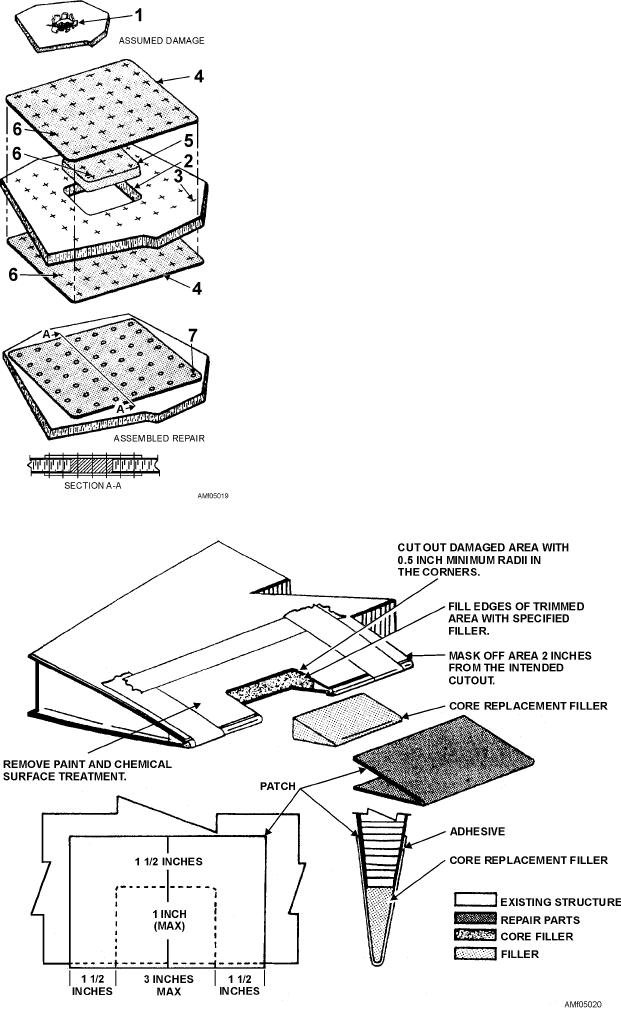

A typical trailing edge repair to a sandwich

construction assembly is shown in figure 5-20.

You may use the lap or flush patch, depending on

the size of the damage, the type of aircraft, and the

assembly or control surface to be repaired. Normally,

the flush patch is used on control surfaces to ensure

aerodynamic smoothness.

Q5-7. When repairing the surface of reinforced

plastics and sandwich construction lami-

nates, what should you use over the build-up

repair area to work out the excess resin and

air bubbles?

Q5-8. In addition to the stepped method, what other

method of repair may be used to ply damage

to solid laminates?

Figure 5-19.--Balsa wood repair with nonflush patch.

Figure 5-20.--Trailing edge repair (sandwich construction).

5-15