Class I is a rain erosion-resistant coating that is

furnished in kit form. This kit consists of a primer,

accelerator, diluting solvent, and neoprene.

Class II is a rain erosion-resistant coating with an

additional surface treatment to minimize radio noise

resulting from precipitation static on the coated surface.

This coating is also supplied in kit form and consists of

a primer, accelerator, diluting solvent, neoprene, and

antistatic coating.

These kits (MIL-C-7439, Classes I and II) are

packaged unaccelerated to provide longer shelf life.

The neoprene is ready to use only after the catalyst

(accelerator) has been added. The material in these kits

should be mixed and applied in accordance with the

instruction sheet supplied by the kit manufacturer.

Observing Safety Precautions

The following general safety precautions should be

observed when you make repairs to reinforced plastic

components. You should review these safety

precautions before attempting any repairs to reinforced

plastics.

1. Local station safety regulations as to fire and

health hazards must be complied with.

2. All solvents are flammable; therefore, observe

proper handling procedures.

3. Personnel involved in the mixing or handling

of catalyzed resin prior to the curing operations should

wear rubber gloves. After using rubber gloves,

personnel should clean their hands with soap and water

and rinse with vinegar to neutralize any catalyst

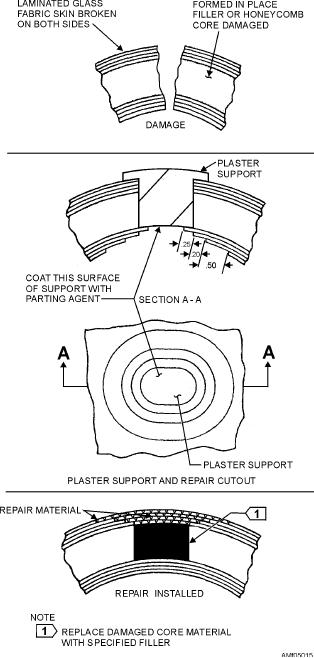

Figure 5-15.--Foam-type puncture repair.

particles.

4. Never mix the catalyst and promoter together,

shielding and interference effects. Always use the

as they are explosively reactive as a mixture. Always

materials recommended in the applicable structural

mix the promoter with the resin first, and then add the

repair manual for refinishing both the interior and

catalyst to the mixture.

exterior surfaces of reinforced plastic components.

5. The toxicity of polyester formulation has not

Reinforced plastic components whose frontal areas

been definitely established. Some of the components

are exposed to high speeds are frequently coated with a

are known to cause nasal or skin irritation to certain

rain erosion coating. Rain erosion coatings protect the

individuals. Adequate ventilation should be provided.

component against pits that are caused by raindrops

6. The sanding operation on glass cloth

hitting the component at high aircraft speeds. These pits

reinforced laminates gives off a fine dust that may cause

or eroded areas can cause delamination of the

skin, eyes, or respiratory irritations. Inhalation of

component glass cloths if allowed to progress

excessive amounts of this dust should be avoided.

unchecked.

Protection should be provided for respiration, eyes, and

Rain erosion-resistant coatings for reinforced

skin.

plastic components conform to Specification

7. Do not store catalyzed resin in an airtight

MIL-C-7439. Coatings that conform to this

container or an unvented refrigerator.

specification are classified as Class I and Class II.

5-11