Repairing Delaminations

REPAIRING SANDWICH CONSTRUCTION

MATERIALS

Facing-to-core voids of less than 2.5 inches in

diameter can usually be repaired by drilling a series of

The repairs discussed here are applicable to

holes 0.06 to 0.10 inch in diameter in the upper facing

structural-type sandwich construction, which consists

over the void area. An expandable forming resin, such

of aluminum alloy facings bonded to aluminum

as Thermofoam 607 or equivalent, is then injected

honeycomb and balsa wood cores.

through the holes with a pressure-type caulking gun.

Repairing Minor Surface Damage

When the void is on the lower surface of the panel, only

sufficient resin must be injected to completely fill the

The most common types of damage to the sur-

void. With voids on the upper surface, the core area

face are abrasions, scratches, scars, and minor dents.

should be filled until the resin comes out of the

These minor surface damages require no repair

injection holes. These holes should be sealed with a

other than the replacement of the original protective

thermosetting epoxy resin adhesive, and the entire

coating to prevent corrosion if no breaks, holes, or

assembly cured with lamps, as required for the adhesive

cracks exist.

system.

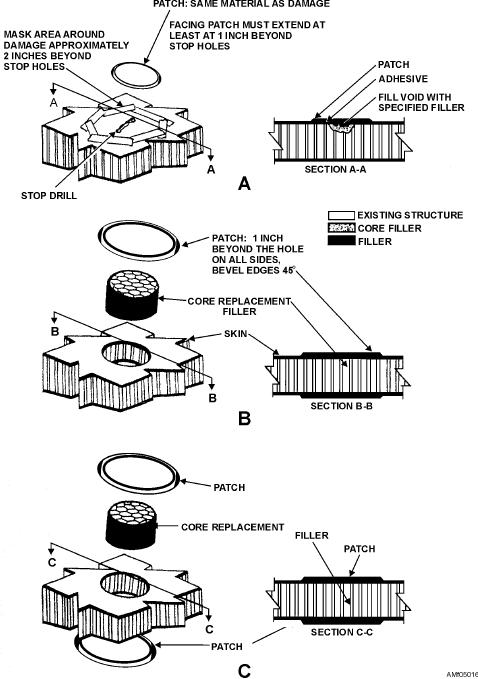

Figure 5-16.--Sandwich construction puncture repair (honeycomb core).

5-12