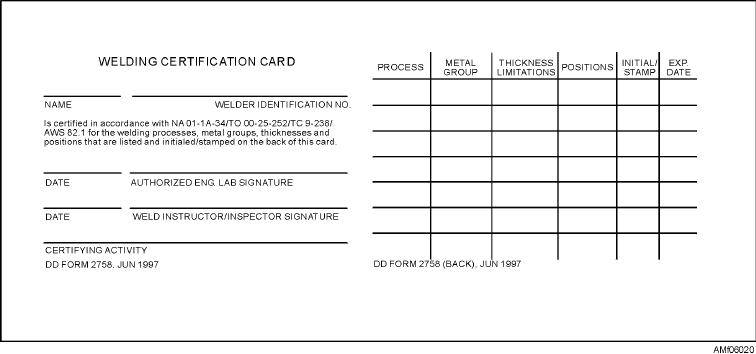

A Welding Certificate (Operator's Card), DD Form

facilities will forward double sets of test plates to the

2758, will be issued for each material category in which

failed welder's command concurrently with the

the welder is qualified. The welding certificate will be

notification of failure. Retest test welds must be com-

filled out, dated, and signed by an authorized

pleted and submitted within 30 days of receipt of

representative of an examination facility. Figure 6-20

notification of failure of first test weld(s). Failure of any

provides a sample of the welding certificate. Figures

retest test welds to meet minimum requirements will

6-21 and 6-22 show a sample Welding Examination

require the welder to satisfactorily complete the Navy

Record (DD Form 2757) and instructions.

training courses N-701-0008/N-701-0010, as appli-

cable, to recertify.

OXYACETYLENE WELDING

Aeronautical equipment welders may weld only on

equipment, components, and items manufactured from

Oxyacetylene welding is a gas welding process. A

the group of metals for which they are currently

coalescence or bond is produced by heating with a gas

certified and for which weld repairs are authorized by

flame or flames obtained from the combustion of

applicable technical publications or directives. Groups

acetylene with oxygen, with or without the application

of metals for which separate and distinct certification is

of pressure, and with or without the use of filler metal.

required are specified in NA 01-1A-34. Separate

A welding torch is used to mix the gases in the proper

certification is also required for oxyfuel brazing

proportions and to direct the flame against the parts to

process.

be welded. The molten edges of the parts then literally

flow together and, after cooling, form one solid piece.

NA 01-1A-34 contains additional informa-

Usually, it is necessary to add extra material to the joint.

tion and guidance relative to qualification,

The correct material in rod form is dipped in and fuses

certification/recertification, and employment of

with the puddle of molten metal from the parent metal

aeronautical equipment welders. It is, however, a

parts.

general series technical manual intended to be

used in conjunction with the OPNAV 4790.2

Acetylene is widely used as the combustible gas

and with specific maintenance/repair/overhaul

because of its high flame temperature when mixed with

manuals/engineering documents. In cases of conflict

oxygen. The temperature, which ranges from

between NA 01-1A-34 and the OPNAV 4790.2

approximately 5,700 to 6,300F, is so far above the

regarding certification/recertification policy, the

melting point of all commercial metals that it provides a

OPNAV 4790.2 takes precedence.

means for the rapid, localized melting essential in

QA/A is responsible for monitoring aeronautical

welding. The oxyacetylene flame is also used in cutting

equipment welder certification/recertification. Refer to

ferrous metals. The oxyacetylene welding and cutting

the OPNAV 4790.2 for specifics.

methods are widely used by all types of maintenance

Figure 6-20.--Welding Certification (DD Form 2758).

6-15