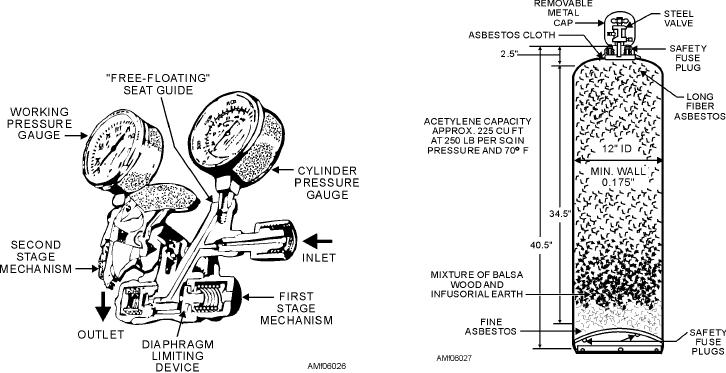

The operation of the two-stage regulator is similar

ACETYLENE CYLINDERS.--Acetylene stored

in principle to the single-stage regulator. The difference

in a free state under pressure greater than 15 psi can be

is that the total pressure decrease takes place in two

made to break down by heat or shock, and possibly

steps instead of one. On the high-pressure side, the

explode. Under pressure of 29.4 psi, acetylene becomes

pressure is reduced from cylinder pressure to

self-explosive, and a slight shock will cause it to

intermediate pressure. On the low-pressure side, the

explode spontaneously. However, when dissolved in

pressure is reduced from intermediate pressure to

acetone, it can be compressed into cylinders at

working pressure. Because of the two-stage pressure

pressures up to 250 psi.

control, the working pressure is held constant, and

The acetylene cylinder (fig. 6-27) is filled with

pressure adjustment during welding operations is not

porous materials, such as balsa wood, charcoal, and

required. A two-stage regulator is shown in figure 6-26.

shredded asbestos, to decrease the size of the open

The acetylene regulator controls and reduces the

spaces in the cylinder. Acetone, a colorless, flammable

acetylene pressure from any standard cylinder that

liquid, is added until about 40 percent of the porous

contains pressures up to 500 psi. It is of the same

material is filled. The filler acts as a large sponge to

general design as the oxygen regulator, but it will not

absorb the acetone, which, in turn, absorbs the

withstand such high pressures. The high-pressure

acetylene. In this process, the volume of the acetone

gauge, on the inlet side of the regulator, is graduated

increases as it absorbs the acetylene, while acetylene,

from 0 to 500 psi. The low-pressure gauge, on the outlet

being a gas, decreases in volume. The acetylene

side of the regulator, is graduated from 0 to 30 psi.

cylinders are equipped with safety plugs, which have a

Acetylene should not be used at pressures exceeding 15

small hole through the center. This hole is filled with a

metal alloy, which melts at approximately 212F or

psi.

releases at 500 psi. When a cylinder is overheated, the

ACETYLENE.--Acetylene is a fuel gas made up

plug will melt and permit the acetylene to escape before

of carbon and hydrogen. It is manufactured by the

a dangerous pressure can build up. The plughole is too

chemical reaction between calcium carbide, a gray

small to permit a flame to burn back into the cylinder if

stone like substance, and water in a generating unit.

the escaping acetylene should become ignited.

Acetylene is colorless, but it has a distinctive odor that

can be easily detected.

WELDING TORCHES.--The oxyacetylene

welding torch is used to mix oxygen and acetylene gas

Mixtures of acetylene and air that contain from 2 to

in the proper proportions, and to control the volume of

80 percent of acetylene by volume will explode when

these gases burned at the welding tip. The torch has two

ignited. However, with suitable welding equipment and

needle valves, one for adjusting the flow of acetylene

proper precautions, acetylene can be safely burned with

oxygen for welding and cutting purposes. When burned

with oxygen, acetylene produces a very hot flame that

has a temperature between 5,700F and 6,300F.

Figure 6-27.--Acetylene cylinder.

Figure 6-26.--Two-stage regulator.

6-20