because the increased heat generated in this method is

puddle. This method is used in welding most of the

likely to cause overheating and burning. When welding

lighter tubing and sheet metals up to 1/8 inch thick

steel with a backhand technique and a reducing flame,

because it permits better control of a small puddle and

the absorption of carbon by a thin surface layer of metal

results in a smoother weld. The forehand technique is

reduces the melting point of the steel. This speeds up

not the best method for welding heavy metals.

the welding operation.

BACKHAND WELDING.--In this method the

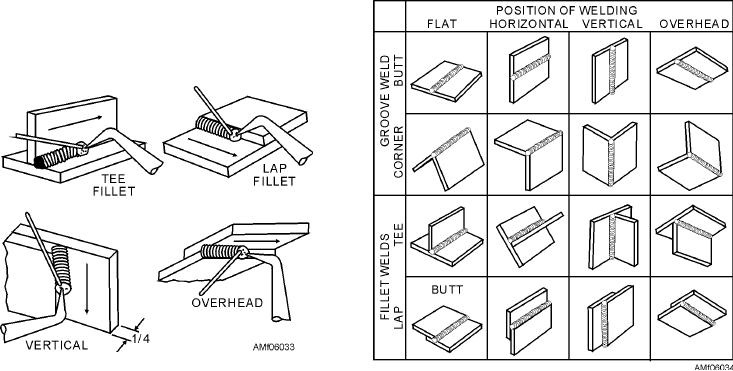

WELDING POSITIONS.--The four basic

torch tip precedes the rod in the direction of welding,

welding positions are shown in figure 6-34. Also shown

and the flame is pointed back at the molten puddle and

are four commonly used joints. Notice that the corner

the completed weld. The end of the rod is placed

joint and butt joint are classified as groove welds, while

between the torch tip and the molten puddle. The

welding tip should make an angle of about 45 to 60

the tee and lap joints are classified as fillet welds.

with the plates or joint being welded (fig. 6-33).

Welding is always done in the flat position when-

ever possible. The puddle is much easier to control, and

Less motion is required in the backhand method

the welder can work longer periods without tiring.

than in the forehand method. If you use a straight

Quite often it is necessary to weld in the overhead,

welding rod, it should be rotated so that the end will roll

vertical, or horizontal position in equipment repair.

from side to side and melt off evenly. You may also

bend the rod and, when welding, move the rod and

The flat position is used when the material is to be

torch back and forth at a rapid rate. If you are making a

laid flat or almost flat and welded on the topside. The

large weld, you should move the rod so as to make

welding torch is pointed downward toward the work.

complete circles in the molten puddle. The torch is

This weld may be made by either the forehand or

moved back and forth across the weld while it is

backhand technique.

advanced slowly and uniformly in the direction of the

The overhead position is used when the material is

weld. You'll find the backhand method best for welding

to be welded on the underside, with the torch pointed

material more than 1/8 inch thick. You can use a

upward toward the work. In welding overhead, you can

narrower "V" at the joint than is possible in forehand

keep the puddle from sagging if you do not permit it to

welding. An included angle of 60 is a sufficient angle

get too large or assume the form of a large drop. The rod

of bevel to get a good joint. It doesn't take as much

is used to control the molten puddle. You should not

welding rod or puddling for the backhand method as it

permit the volume of flame to exceed that required to

does for the forehand method.

obtain a good fusion of the base metal with the filler

By using the backhand technique on heavier

rod. Less heat is required in an overhead weld because

material, it is possible to obtain increased welding

the heat naturally rises.

speeds, better control of the larger puddle, and more

complete fusion at the root of the weld. Further, by

using a reducing flame with the backhand technique, a

smaller amount of base metal is melted while welding a

joint. Backhand welding is seldom used on sheet metal

Figure 6-33.--Backhand welding.

Figure 6-34.--Four basic welding positions.

6-25