Acetylene Safety Precautions

sufficient filler metal is added to fuse or melt each plate

edge completely and to reinforce the joint.

Acetylene safety precautions should be rigidly

Light sheets are welded as shown in view B of

observed and enforced. Some of the more important

figure 6-41. No preparation is necessary other than to

precautions to remember are as follows:

clean the edges and tack weld them in position. The

1. Store acetylene cylinders in an upright

edges are fused together so no filler metal is required.

position. They must be securely fastened to prevent

The heavy plate joint, as shown in view C of figure

shifting or falling. Do not place cylinders on sides,

6-41, requires that the edges be beveled to secure good

drop, or handle roughly. If horizontal stowage is

penetration and fusion of the sidewalls. Filler metal is

necessary, or an acetylene cylinder is inadvertently left

used in this joint.

lying in a horizontal position, it must be placed in an

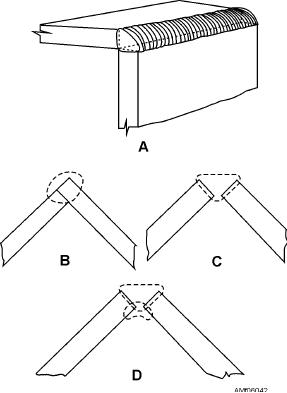

CORNER JOINTS.--Corner joints are used to

upright position for a minimum of 2 hours before it can

join two members located approximately at right angles

be used. (Otherwise, acetone in which the acetylene is

to each other in the form of an L. The fillet weld corner

dissolved will be drawn out with the gas.) Avoid

joint (view A of fig. 6-42) is used in the construction of

damaging the valves or fuse plugs to prevent leakage.

boxes, box frames, and similar fabrications.

2. Store acetylene cylinders in a well-protected,

The closed corner joint (view B of fig. 6-42) is used

well-ventilated, dry place, away from heating devices

on lighter sheets when high strength is not required at

or combustible materials.

the joint. In making the joint by oxyacetylene welding,

3. Use acetylene from cylinders only through

the overlapping edge is melted down, and little or no

pressure-reducing regulators. Do not use acetylene at

filler metal is added. When the closed joint is used for

pressures greater than 15 psi.

heavy sections, the lapped plate is V-beveled or

U-grooved to permit penetration to the root of the joint.

4. Open the acetylene valve slowly, 1/4 to 1/2

turn. This will permit an adequate flow of gas. Never

The open corner joint (view C of fig. 6-42) is used

open the valve more than 1 1/2 turns of the spindle.

on heavier sheets and plates. The two edges are melted

down, and filler metal is added to fill up the corner.

5. Keep sparks, flames, and heat away from

acetylene cylinders.

Corner joints on heavy plates are welded from both

sides, as shown in view D of figure 6-42. The joint is

6. Turn the acetylene cylinder so that the valve

first welded from the outside, and then reinforced from

outlet will point away from the oxygen cylinder.

the backside with a seal bead.

7. Do not interchange hose, regulators, or other

apparatus intended for oxygen with those intended for

acetylene.

8. Use only approved hoses and fittings with

acetylene equipment. Pure copper, or copper alloys

containing 67 to 99 percent copper, must not be used in

piping or fittings for handling acetylene (except

blowpipe or torch tips).

9. Test for leaks with soapy water--not with an

open flame.

10. Make no attempt to transfer acetylene from one

cylinder to another, refill an acetylene cylinder, or mix

any other gas or gases with acetylene.

11. Keep valves closed on empty cylinders.

12. Should an acetylene cylinder catch fire, use a

wet blanket to extinguish the fire. If this fails, spray a

stream of water on the cylinder to keep it cool.

13. Crack each cylinder valve for an instant to blow

dirt out of the nozzles before attaching the pressure

Figure 6-42.--Corner joints for sheets and plates.

6-28