is held rigidly in the torch by means of a collet that

Alternating current, high-frequency (ACHF)

screws into the body of the torch. A variety of collet

welding is a combination of dc straight polarity and dc

sizes are available so different diameter electrodes can

reverse polarity. One half of the complete ac cycle is

be used. Gas is fed to the weld zone through a nozzle,

DCSP and the other half is DCRP. Unfortunately,

which consists of a ceramic cup. Gas cups are threaded

oxides, scale, and moisture on the work piece often tend

into the torch head to provide directional and

to prevent the full flow of current in the reverse polarity

distributional control of the shielding gas. The cups are

direction. If no current whatsoever flowed in the reverse

interchangeable to accommodate a variety of gas flow

polarity direction during a welding operation, the

rates. Gas cups vary in size. The size you should use

partial or complete stoppage of current flow would

depends upon the type and size of torch and the

cause the arc to be unstable and sometimes go out. To

diameter of the electrode.

prevent this, ac welding machines incorporate a

high-frequency current flow unit. The high-frequency

Pressing a control switch on the torch starts the

current is able to jump the gap between the electrode

flow of both the current and gas. On some equipment,

and the work piece, piercing the oxide film and forming

the flow of current and gas is energized by a foot

a path for the welding current to flow.

control. The advantage of the foot control is that the

variable current flow can be used as the end of the weld

Welding Equipment

is reached. By gradually decreasing the current, it is

less likely for a cavity to remain in the end of the weld

Gas tungsten-arc welding equipment is produced

puddle and less danger of cutting short the shielding

by many manufacturers. For this reason, it is very

gas.

important to remember that the equipment being

discussed in this chapter is only one of the many types

ELECTRODES.--Pure tungsten, or tungsten

that can be found throughout the Navy. However, the

alloyed with thorium or zirconium, is the best electrode

functions of similar component parts of different makes

for gas tungsten-arc welding. The addition of thorium

of machines are identical, although they may not appear

increases the current capacity and electron emission,

to be so.

keeps the tip cooler at a given level of current,

minimizes movement of the arc around the electrode

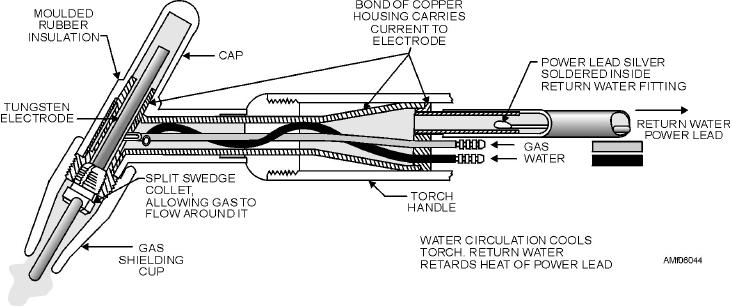

TORCHES.--Manually operated torches are

tip, permits easier arc starting, and the electrode is not

constructed to conduct both the welding current and the

as easily contaminated by accidental contact with the

inert gas to the weld zone. These torches are either air

work piece.

or water-cooled. Air-cooled torches are designed for

welding light gauge materials where low current values

The diameter of the electrode selected for a

are used. Water-cooled torches (fig. 6-44) are

welding operation is governed by the welding current to

recommended when the welding requires amperages

be used. Larger diameter tungsten electrodes are

over 200 amps. A circulating stream of water flows

required with reversed polarity than with straight

around the torch to keep it from overheating. The

polarity.

tungsten electrode, which supplies the welding current,

Figure 6-44.--Typical water-cooled GTA welding torch.

6-30