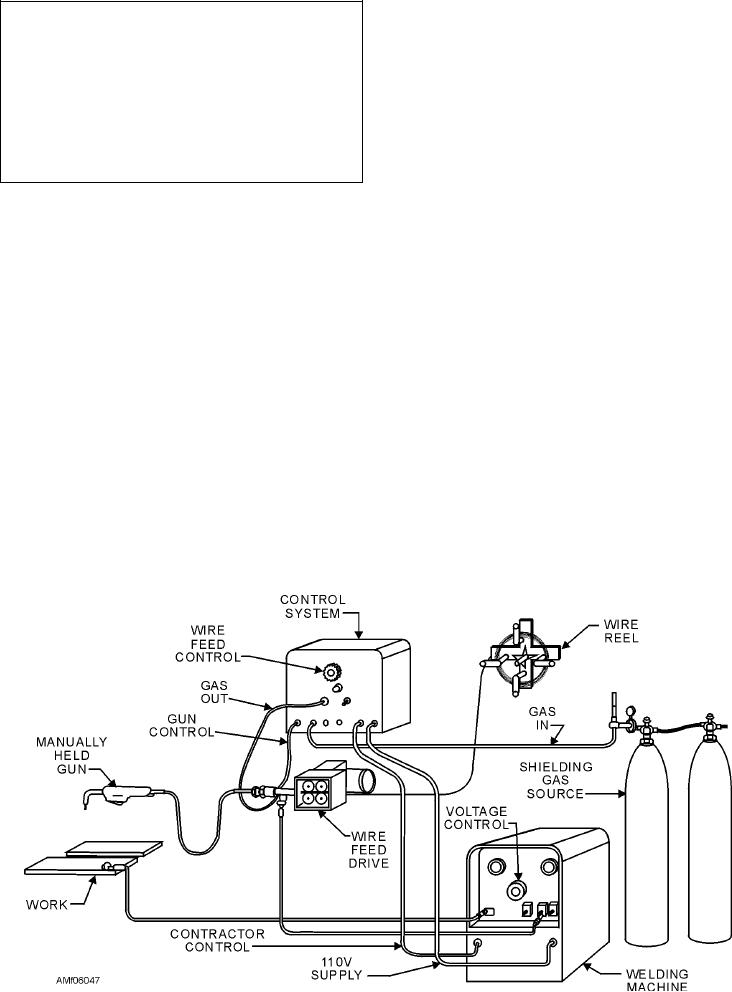

GMA Welding Equipment

CAUTION

There are numerous types and models of GMA

If you are using a water-cooled cup, do not allow

welding equipment used in the Navy. Each must have a

the cup to come in contact with the work when the

source of direct current reverse polarity (DCRP)

current is on. The hot gases may cause the arc to jump

welding current, a wire feed unit for feeding the wire

the electrode to the cup instead of the plate, thereby

filler metal, a welding gun for directing the wire filler

damaging the cup. Be sure that the water flow is set

and shielding gas to the weld area, and a gas supply.

according to the manufacturer's recommendations.

Figure 6-47 shows GMA welding equipment.

POWER SUPPLY.--The recommended machine

GAS METAL-ARC WELDING

for gas metal-arc welding is a rectifier or motor

generator that supplies direct current with normal limits

Gas metal-arc (GMA) welding is a process that

of 200 to 250 amperes. Direct current reverse polarity is

produces fusion by heating with an electric arc between

most generally used because it provides maximum heat

a consumable wire electrode and the work. The arc and

for better melting, deeper penetration, and excellent

weld puddle are shielded from the atmosphere by a gas,

cleaning action.

or a gas and a flux. The shielding gas protects the

Two types of direct-current power sources are used

molten weld metal from oxidation or contamination by

for gas metal-arc welding--the constant-current type

the surrounding atmosphere.

and the constant-voltage type. The constant-current

The consumable-wire electrode for GMA welding

power source is used if the controls and wire-driven

is fed through the torch to the welding arc at the same

mechanism control the arc length by varying the

rate as the heat of the arc melts off the end of the

wire-drive speed. In this case, a change in the arc length

electrode. The shielding gas flows through the torch to

causes a change in the arc voltage. The control circuit

the arc area. The melting rate of the filler wire depends

senses this change and varies the wire-feed speed to

on the level of the welding current, but must be the

bring the arc length back to the desired value.

same as the feeding rate to maintain a constant arc

When arc length is controlled through changes in

length. This means that a constant balance must be

welding current, constant-voltage power supplies are

maintained between the welding current and

used. The wire-feed speed is constant. Any changes in

wire-feeding rate.

Figure 6-47.--GMA welding equipment.

6-32