To produce good welds, the tungsten electrode

must be shaped correctly. The general practice is to use

a pointed electrode with dc welding, and a spherical

end with ac welding. It is also important that the

electrode be straight, otherwise the gas flow will be

off-center from the arc.

SHIELDING GASES.--Shielding gas for gas

tungsten-arc welding can be argon, helium, or a

mixture of argon and helium. Argon is the most popular

shielding gas used in the gas tungsten-arc process.

Helium is rarely used because of its higher cost as

compared to argon. In addition, since argon is heavier

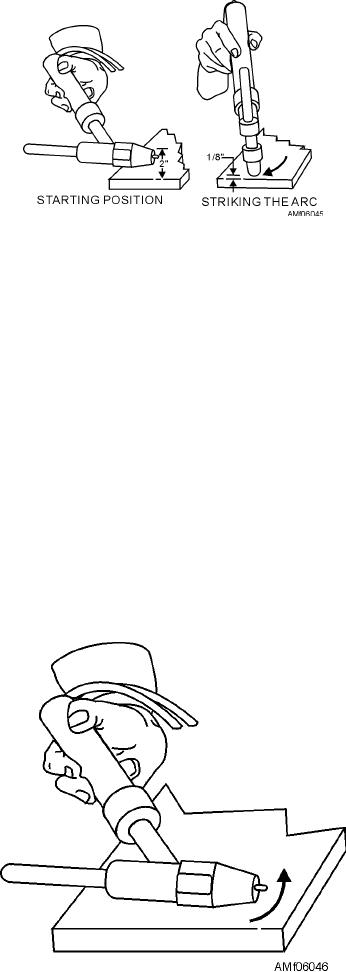

Figure 6-45.--Starting the arc.

than air, it provides a better blanket over the weld. A

mixture of argon and helium is sometimes used in

made rapidly to provide the maximum amount of gas

welding metals that require a higher heat input.

protection to the weld zone.

Welding Procedures

If a dc machine is used, hold the torch in the same

position; but in this case, the electrode can touch the

Before you begin the welding process, be sure to

plate to start the arc. When the arc is struck, withdraw

observe the following preliminary steps:

the electrode so it is about 1/8 inch above the work

1. Check all electrical circuit connections to make

piece.

sure they are tight.

STOPPING THE ARC.--To stop an arc on the ac

2. Check for proper diameter electrode and cup

or dc machine, swing the electrode back to the

size.

horizontal position, as shown in figure 6-46. Make this

movement rapidly to avoid marring or damaging the

3. Adjust the electrode so that it extends the

weld surface.

appropriate distance beyond the edge of the gas cup for

the particular joint being welded.

Some machines are equipped with a foot pedal to

permit a gradual decrease of current. With such control,

4. Check the electrode to be certain that it is

it is easier to fill the crater completely and prevent

firmly held in the collet. If the electrode moves in the

crater cracks.

nozzle, tighten the collet holder or gas cup. Be careful

not to over tighten the gas cup because this will strip the

threads.

5. Set the machine for the correct welding

amperage.

6. If a water-cooled torch is to be used, turn on the

water.

7. Turn on the inert gas and set it to the correct

flow.

STARTING THE ARC.--If you are using an ac

machine, the electrode should not touch the metal to

start the arc. To strike the arc, first turn on the welding

current and hold the torch in a horizontal position about

2 inches above the work. Angle the end of the torch

toward the work piece so the end of the electrode is 1/8

inch above the plate. Figure 6-45 shows the procedure

for starting the arc. The high-frequency current will

jump the gap between the electrode and the plate,

establishing the arc. Be sure the downward motion is

Figure 6-46.--Breaking the arc.

6-31