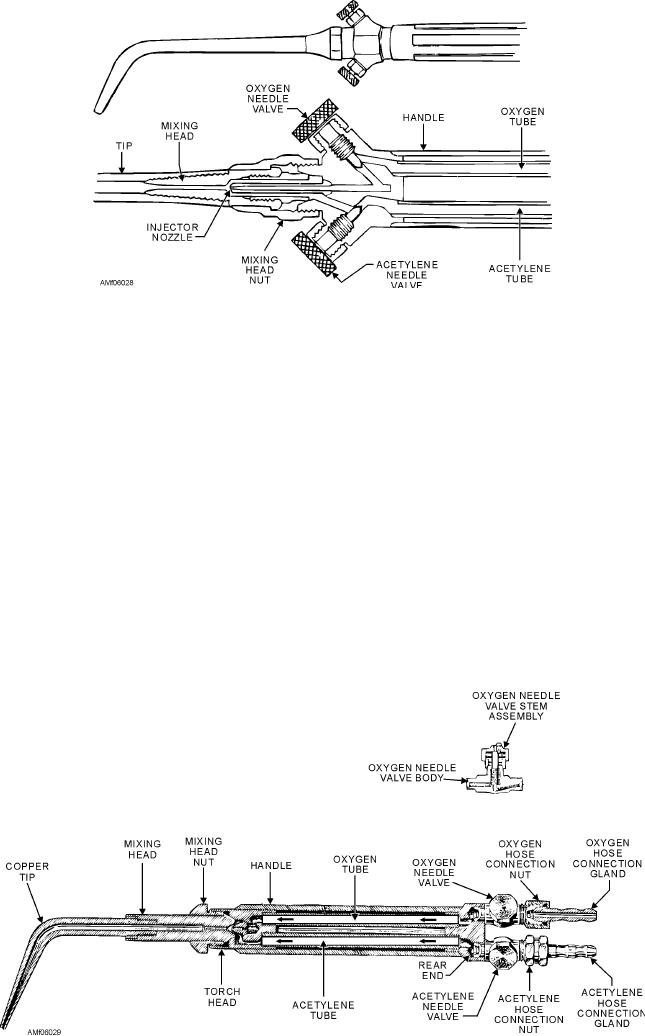

Figure 6-28.--Mixing head for injector-type welding torch.

The equal pressure torch (fig. 6-29) is designed to

and the other for adjusting the flow of oxygen. In

operate with equal pressures for the oxygen and

addition, there are two tubes, one for oxygen and the

acetylene. The pressure ranges from 1 to 15 psi. This

other for acetylene; a mixing head; inlet nipples for the

torch has certain advantages over the low-pressure type

attachment of hoses; a tip; and a handle. The tubes and

because the flame can be more readily adjusted, and

handle are made of seamless hard brass, copper-nickel

since equal pressures are used for each gas, the torch is

alloy, stainless steel, or other noncorrosive metals of

less susceptible to flashbacks.

adequate strength.

The welding tips are made of hard, drawn,

There are two types of welding torches--the

electrolytic copper or 95-percent copper and 5-percent

low-pressure or injector type and the equal-pressure

tellurium. They are made in various styles and types,

type. In the low-pressure or injector type (fig. 6-28), the

some having a one-piece tip either with a single orifice

acetylene pressure is less than 1 psi. A jet of

or a number of orifices, and others with two or more tips

high-pressure oxygen is used to produce a suction

attached to one mixing head. The diameters of the tip

effect to draw in the required amount of acetylene. This

orifices differ to control the quantity of heat and the

is accomplished by the design of the mixer in the torch,

type of flame. These tip sizes are designated by

which operates on the injector principle. The welding

numbers that are arranged according to the individual

tips may or may not have separate injectors designed

integrally with each tip.

Figure 6-29.--Equal pressure welding torch.

6-21