wheel assemblies using tubeless tires. Install the wheel

seal on the flange. Secure the locking ring according to

the assembly instructions required by the applicable

wheel manual.

Tire Inflating

According to Federal Specification BB-N-411,

water-pumped nitrogen should be used to inflate tires.

When nitrogen is not available, dry, oil-free air may be

used. Nitrogen is provided in a number of mobile carts.

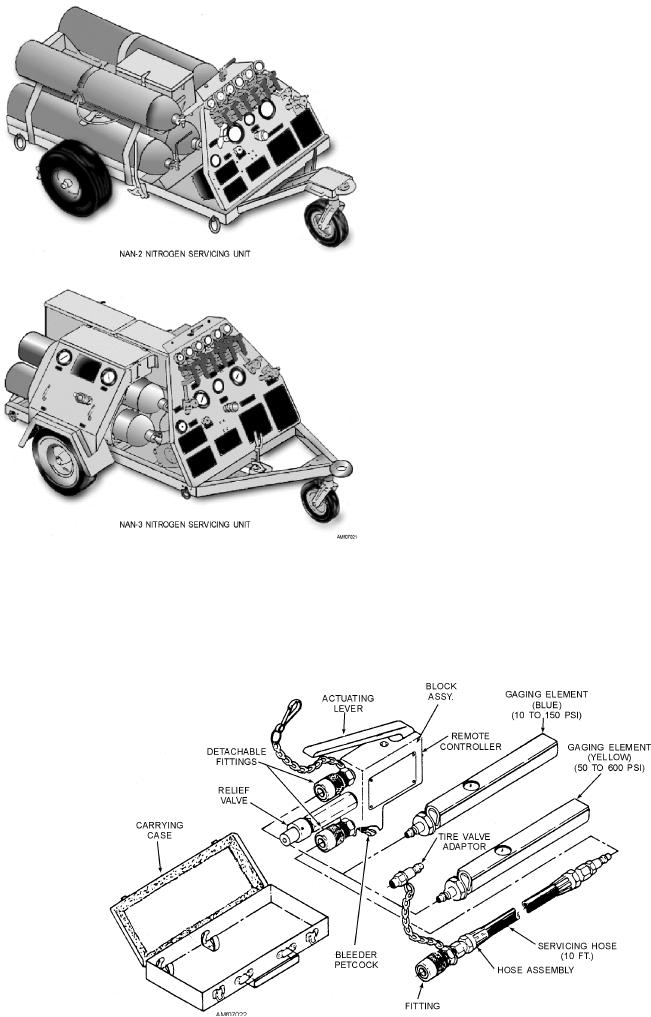

The NAN-2 and NAN-3 carts are shown in figure 7-21.

Tire shops are generally equipped with a bulkhead

nitrogen outlet.

All high-pressure inflation sources should be

equipped with a regulator that limits the line pressure to

the remote inflator assembly. The regulator should be

set to provide a controlled inlet pressure to the inflator.

It should not exceed the required tire inflation pressure

by more than 50 percent or 600 psi, whichever is less.

The tire inflator assembly kit is an excellent

maintenance device if it is used and cared for according

to the NAVAIR 17-1-123 manual. See figure 7-22. This

manual includes the operation instructions, main-

tenance instructions, and illustrated parts breakdown

for the remote inflator assembly and dual chucks stem

gauge.

Figure 7-21.--Nitrogen servicing units.

The tire inflator assembly kit consists of a remote

controller, a low- and high-pressure gauging element,

removed) in the wheel assembly. Removing the valve

and a 10-foot service hose. The remote inflator

core prevents unseating the wheel seal by the pressure

assembly should be calibrated upon initial receipt,

built up when the tire is installed. The wheel seal should

before being placed in service, and every 6 months

be lubricated with the same lubricant and in the same

thereafter. The unit is equipped with a built-in relief

manner as previously mentioned for split or divided

Figure 7-22.--Tire inflator assembly kit.

7-18