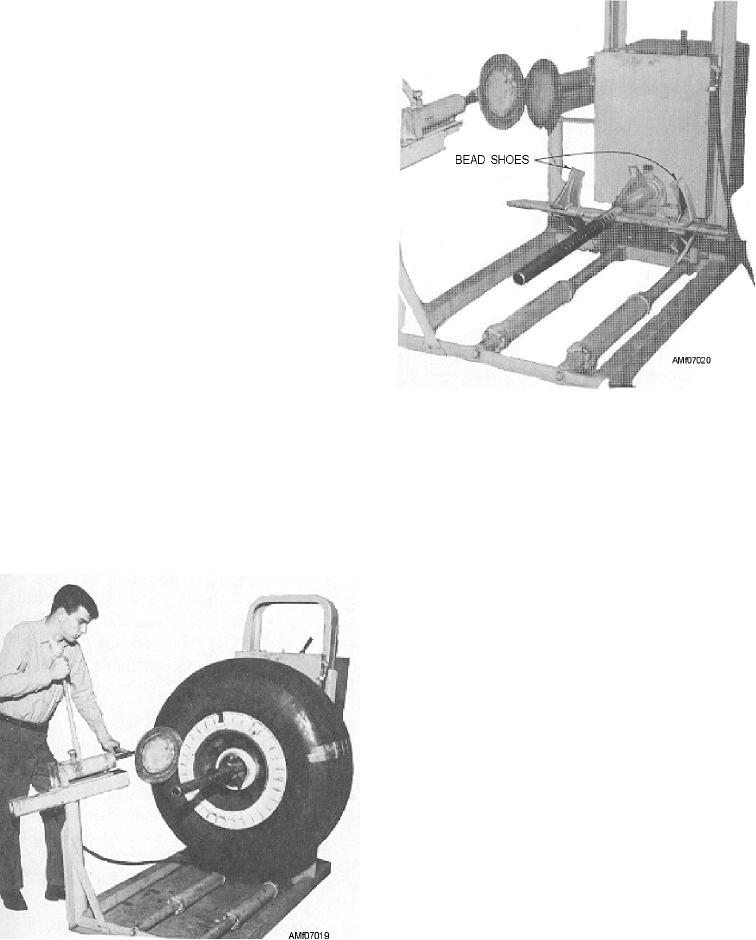

7. Rotate the tire by pushing the tire rotating

toggle to the right. Position the front bead-breaking disc

against the outside bead of the wheel flange. You

should adjust the position of the hydraulic pump

assembly by loosening the position lockpin and sliding

the pump to the proper position. After turning the pump

release valve clockwise as far as it will go, apply

hydraulic pressure against the bead by pumping the

handle, as shown in figure 7-19. Use the guide handle to

properly position the disc. Push the bead back far

enough to allow the removal of the lockring or loose

flange.

8. Remove the lockring and loose flange. You

should use the bead shoes to hold the bead back while

you are removing the lockring. See figure 7-20. Release

and retract the front bead-breaking disc by turning the

release valve counterclockwise.

9. Repeat the bead-breaking operation against the

rear surface of the tire with the rear bead-breaking

assembly.

Figure 7-20.--Shaft arranged to hold tire bead while

removing lockring.

10. After the beads are broken on divided (split)

wheels, remove the nuts and bolts while the wheel

assembly is mounted on the machine.

according to the bead-breaking procedure. If the tire

DISMOUNTING DIVIDED (SPLIT)

has a tube, remove the hex nut and push the valve away

WHEELS.--The tire bead should be broken away

from the seated position. This will prevent damage to

from the wheel and the nuts and bolts removed

the inner tube valve attachment when you break the tire

bead loose. Then, remove the wheel assembly from the

tire. If the tire is tubeless, remove the wheel seal

carefully from the wheel half and place it on a clean

surface. Wheel seals in good condition may be reused if

replacement seals are not available. If the tire has a

tube, remove it. Inner tubes can be reused if they are in

good condition and less than 5 years old.

DISMOUNTING DEMOUNTABLE FLANGE

WHEELS.--The tire bead should be broken away

from the wheel according to the bead-breaking

procedure. If the tire has a tube, you should remove the

hex nut and push the valve away from the seated

position. This will prevent damage to the inner tube

valve attachment when you break the bead.

If you have trouble removing the flange while the

wheel is mounted on the bead-breaking machine,

remove the tire from the machine. Lay the tire and

wheel assembly flat with the demountable flange side

up. Drive the demountable flange down by tapping it

with a rubber, plastic, or rawhide-faced mallet. This

should enable you to remove the locking ring.

Figure 7-19.--Using bead-breaking pump.

7-16