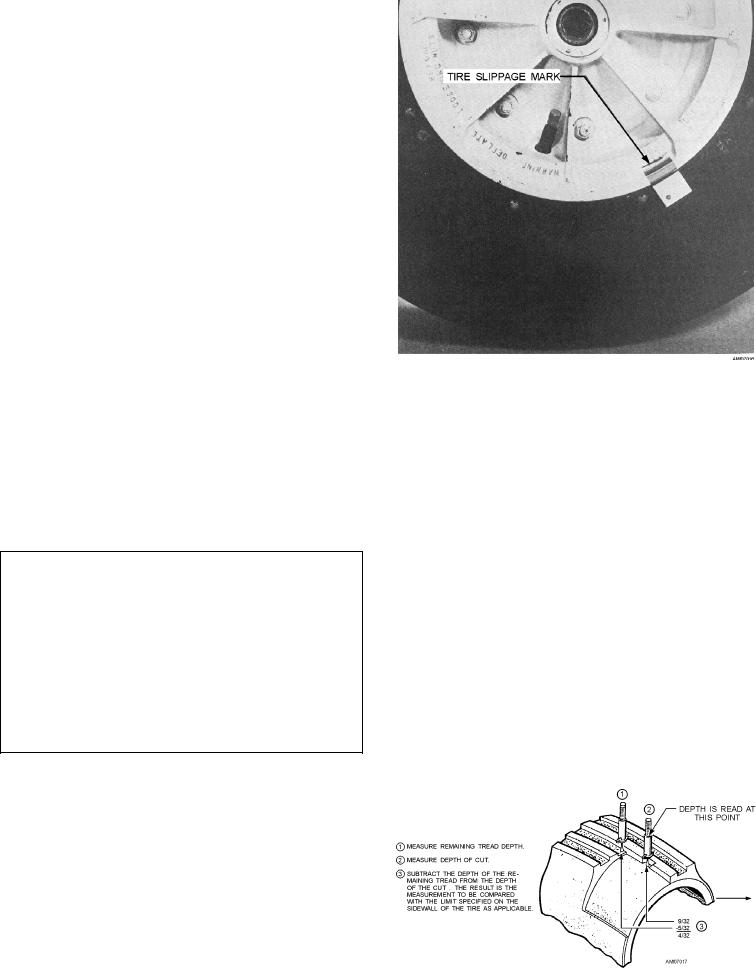

rim, as shown in figure 7-16. Tires should be inspected

for slippage on the rim after each flight. If the markings

do not align within one-fourth of an inch, the wheel

assembly should be replaced and the defective

assembly forwarded to the AIMD or IMA for repair.

Failure to correct tire slippage may cause the valve stem

to be ripped from the tube.

Tire treads should be inspected to determine the

extent of wear. The maximum allowable thread wear

for tires without wear depth indicators is when the tread

pattern is worn to the bottom of the tread groove at any

spot on the tire. The maximum allowable tread wear for

tires with tread wear indicators is when the tread pattern

is worn either to the bottom of the wear depth indicator

or the bottom of the tread groove. These limits apply

regardless of whether the wear is the result of skidding

or normal use.

The tread and sidewall should be examined for cuts

Figure 7-16.--Tire slippage mark.

and embedded foreign objects. Figure 7-17 shows the

method for measuring the depth of cuts, cracks, and

Dismounted Inspection

holes. Glass, stones, metal, and other materials

embedded in the tread should be removed to prevent cut

Whenever a tire has been subjected to a hard

growth and eventual carcass damage. A blunt awl or

landing or has hit an obstacle, it should be removed in

screwdriver may be used for this purpose. You should

accordance with the applicable MIM and dismounted

be careful to avoid enlarging the hole or damaging the

for a complete inspection to determine if any internal

cord body fabric.

damage has occurred. The tire beads should be spread,

and the inside of the tire inspected with the aid of a

light. If the lining has been damaged or there are other

WARNING

internal injuries, the tire should be removed from

service. You should check the entire bead area and the

When you are probing for foreign objects, be

area just above the bead for evidence of rim chafing and

sure you keep the probe from penetrating deeper into

damage. Check the wheel for damage that may damage

the tire. Objects being pried from the tire frequently

the tire after it is mounted.

are ejected suddenly and with considerable force. To

avoid eye injury, you should wear safety glasses or a

AIRCRAFT TIRE MAINTENANCE

face shield. You can place a gloved hand over the

object to deflect it.

Aircraft tire inspection and maintenance have

become more critical through the years because of

Aircraft should not be parked in areas where the

tires may stand in spilled hydraulic fluids, lubricating

oils, fuel, or organic solvents. If any of these materials

is accidentally spilled on a tire, it should be

immediately wiped with a clean, absorbent cloth. The

tires should then be washed with soap and thoroughly

rinsed with water.

You should take extra care when you inspect

mounted helicopter tires. Because of the long intervals

between tire changes, helicopter tires are subject to

Figure 7-17.--Method of measuring depth of cuts, cracks, and

holes.

weather and UV damage.

7-14