CHAPTER 10

HOSE AND TUBING FABRICATION AND

MAINTENANCE

HOSE AND HOSE ASSEMBLIES

INTRODUCTION

You are responsible for maintaining a portion of the

LEARNING OBJECTIVES: Identify the

hundreds of feet of fluid and air lines and various

various types of hose and hose assem-

hardware and seals found in modern-day aircraft. The

blies. Identify hardware, tools, equipment,

maintenance of these lines frequently involves

maintenance practices, and age control

fabrication and replacement of hose/tubing assemblies.

requirements for naval aircraft. Recognize

To be able to select the proper type of hose and tubing

maintenance practices for hose and hose

and their hardware, you will need a basic knowledge of

assemblies.

the type, size, and material from which items are to be

Hose assemblies are used to connect moving parts

made. Hose and tubing assemblies are used to transport

with stationary parts and in locations subject to severe

liquids or gas (usually under pressure) between various

v i b r a t i o n . H o s e a s s e m b l i e s a r e h e av i e r t h a n

components of the aircraft system. Hose and tube

aluminum-alloy tubing and deteriorate more rapidly.

assemblies are used in aircraft for fuel, oil, oxidizer,

They are used only when absolutely necessary. Hose

coolant, breathing oxygen, instruments, hydraulic, and

assemblies are made up of hose and hose fittings. A

vent lines. You must be familiar with the procedures for

hose consists of multiple layers of various materials.

testing and fabricating hose and tubing assemblies, and

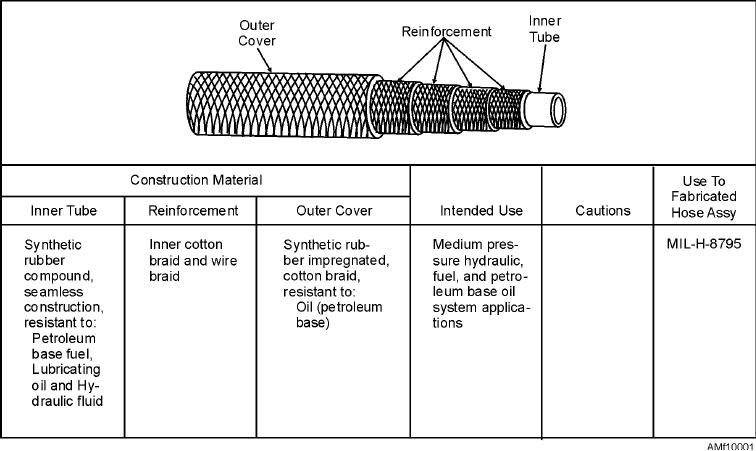

An example of the hose most often used in

you must recognize the various tools and equipment

medium-pressure applications is shown in figure 10-1.

and how to identify the different uses of hose and tubing

in naval aircraft.

Figure 10-1.--Medium pressure synthetic rubber hose, MIL-H-8794.

10-1