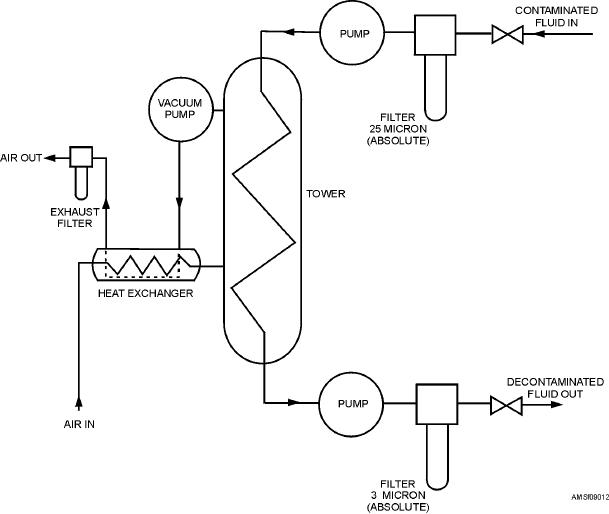

Figure 9-12.--Fluid purification system.

cleaning procedures, and perform tests upon

until a quantity of fluid equal to the equipment

reservoir capacity has passed through the unit. Closely

completion of purging to ensure satisfactory removal

monitor the reservoir level during the operation,

of all cleaning agents. Whenever possible, purging

adding new filtered fluid as required. This prevents the

operations are to be accomplished at a naval aviation

reservoir level from dropping below the one-third full

depot facility (NADEP). Intermediate maintenance

point.

activities are not authorized to perform system purging

without direct depot supervision.

Take a sample and analyze the output and the

reservoir fluids. If the contamination level shows

Q9-28. Where is the nonbypass filter installed on a

improvement but is still unacceptable, repeat the

support equipment unit used to test or service

flushing operation. If extensive flushing fails to

an aircraft hydraulic system?

decontaminate the equipment, you should request

Q9-29. What can be used in place of an approved

assistance from the supporting engineering activity.

metal closure to protect fittings on a hydraulic

test stand?

Upon successful completion of system flushing,

recirculation clean the equipment for a minimum

Q9-30. What is the purpose of air bleeding a piece of

period. Then, take a sample from the system to verify

hydraulic support equipment?

the contamination level as being acceptable. When

Q9-31. What is one method used to keep air from

you have done this, service the reservoir.

being introduced into a hydraulic system

PURGING.--Purging of a support equipment

when you are replacing a component?

hydraulic system is performed only upon

Q9-32. What function must be accomplished prior to

recommendation from, and under the direct

connecting a test stand to an aircraft?

supervision of, the cognizant engineering activity. It is

the responsibility of the cognizant engineering activity

Q9-33. What cleaner is used to clean all sampling

points on a hydraulic test stand?

to select the required cleaning agents, provide detailed

9-20