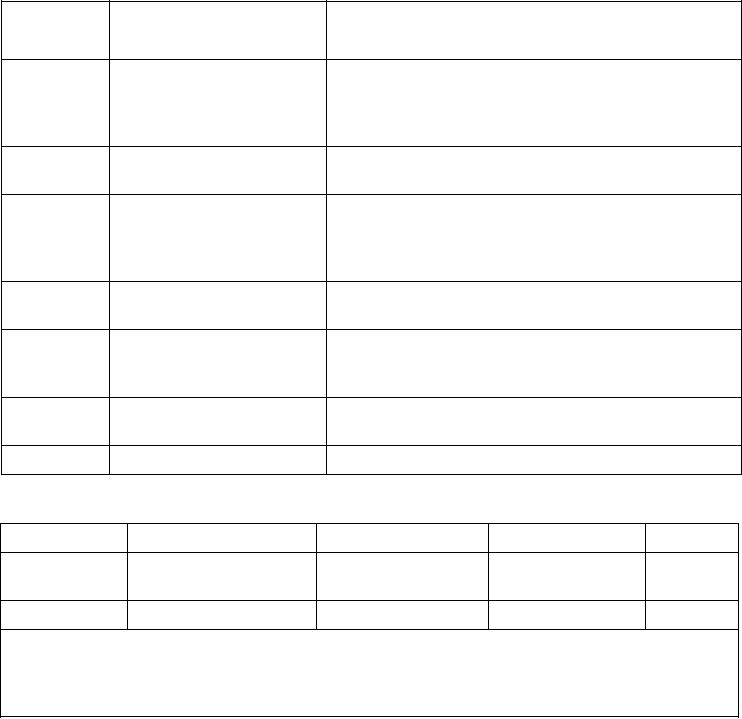

Table 9-1.--A/M27T-5 Main Control Panel Controls and Indicators--Continued.

FIG. 9-5

INDEX NO.

CONTROL/INDICATOR

FUNCTION

25

H.P. GAUGE TEST port

Allows application of hydraulic fluid from external source for use in

testing and calibrating HIGH PRESSURE GAUGE. Used only

when H.P. GAUGE SHUTOFF VALVE (on secondary control

panel) is closed.

26

High pressure gauge calibrating

Used to calibrate HIGH PRESSURE GAUGE when H.P.

screw

SHUTOFF valve (on secondary control panel) is closed.

27

HIGH PRESSURE GAUGE

Indicates hydraulic pressure (0 to 6000 psi scale) at PRESSURE

OUTLET ports. closing H.P. GAUGE SHUTOFF valve (on

secondary control panel) isolates HIGH PRESSURE GAUGE from

hydraulic system, enabling testing and calibration of gauge.

Indicates hydraulic fluid temperature (20 to 220F scale) at

28

FLUID TEMPERATURE

GAUGE

hydraulic pump high pressure inlet port.

29

Ignition switch S1

When set to IGNITION ON turns on panel lights DS1, DS2, and

DS3 and IGNITION ON indicator DS9. Switches battery current to

power supply electrical system, enabling diesel engine start-up.

30

IGNITION ON indicator (DS9)

When illuminated, indicates ignition switch S1 is set to IGNITION

ON.

Indicates diesel engine coolant temperature (100 to 250F scale).

31

HEAD TEMPERATURE gauge

Table 9-2.--Portable Hydraulic Test Stands

MODEL

MFR & P/N (CAGE)

PUBLICATION

MRC

TEC

A/M27T-5

Hydraulic International

NA 17-15BF-89

17-600-127-6-1

GGJZ

88A4-J1000-1 (56529)

A/M27T-7

68A5-J1000 (56529)

NA 17-15BF-91

17-600-150-6-1

GGJV

NOTES:

1. A/M27T-5/-7 test stands are preferred equipment and shall be used whenever available.

2. All electric motor-driven units operate from 220/440-V, 3-phase power source.

NOTE: When actually cleaning and deaerating

gauges; they should be at or near zero. Clean and

the test stand, you should follow the procedures

connect the service ends of the external pressure and

contained in the applicable manuals.

return line hoses to the hose storage (recirculation)

Set up the test stand to provide fluid flow from the

manifold on the equipment. If the manifold is

internal reservoir through the external service hoses

equipped with a shutoff valve, place the valve in open

and interconnecting manifold. Place the pump

position.

pressure compensator at its lowest setting, and make

Start test stand engine (or motor) according to the

sure that the manifold and service outlet valves (if

applicable operating instructions. Allow the engine to

present) are in the open position. The high-pressure

warm up to its normal operating temperature.

gauge should indicate a value less than 600 psi. Allow

Recirculation clean and deaerate the hydraulic fluid in

the test stand to recirculation clean for 3 to 5 minutes.

the test stand. Perform both operations at the same

Monitor the fluid temperature throughout the cleaning

cycle. Make sure that maximum operating limits are

time.

9-9