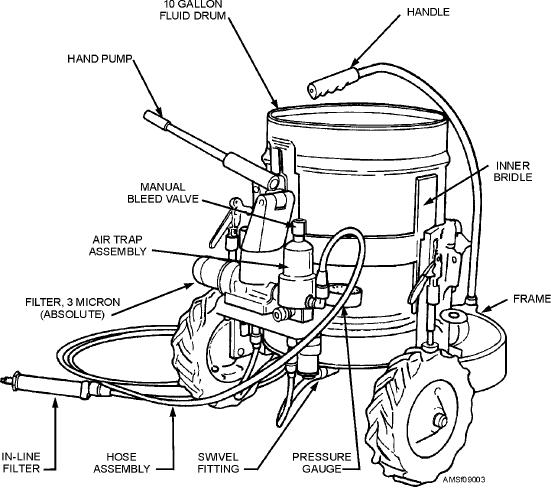

Figure 9-3.--Model 310 fluid service cart.

the cart in its upright position, may be positioned

CHECKING AIRCRAFT HYDRAULIC

around and secured to a 10-gallon fluid drum without

FLUID LEVELS

lifting the drum. Once it is installed in the bridle, you

can move the drum using the dolly, or tilt it back 90

There are specific procedures for checking

degrees from vertical to the operating position.

hydraulic fluid levels in each model of aircraft. These

procedures must be followed to make sure the system

Hydraulic fluid is removed through a swivel fitting

operates at the required fluid level. Fluid level is

installed in a 2-inch hole. The swivel fitting is

generally determined by an indicating device at the

connected by a flexible hose to a single-action pump

system reservoir. The type of indicator used varies

that has a displacement of 2 fluid ounces per stroke at 0

with the aircraft model. Sight-glass, gauge, and

to 250 psi. A replaceable 3-micron (absolute)

piston-style indicators are commonly used.

disposable filter installed at the pump assembly base

removes particulate contamination from the fluid

There is close tolerance between the operating

being delivered to the suction side of the pump. A

parts of equipment used in aircraft hydraulic systems

check valve in the filter assembly prevents operation

and the level of hydraulic fluid contamination;

without an installed filter element.

therefore, do not introduce foreign matter into a

system being serviced. All servicing must be

Filtered fluid from the hand pump is routed to an

accomplished by qualified personnel using authorized

air trap assembly, which contains a special chamber

fluid-dispensing equipment.

that removes any free air present in the fluid. The air

trap assembly contains a manual bleed valve for

The information given here gives general guidance

venting collected air and a 0- to 300-psi pressure gauge

and requirements to follow when fluid servicing

for monitoring output pressure. Fluid is delivered to

hydraulic systems and components. Remember, you

the system or component being serviced by a 15-foot

need to follow the procedures contained in the

service hose. A 3-micron, in-line filter assembly is

applicable technical manuals when you actually

located near the discharge end of the service hose to

service hydraulic systems and components. When you

ensure against system contamination.

service these systems, use approved fluid-dispensing

9-4