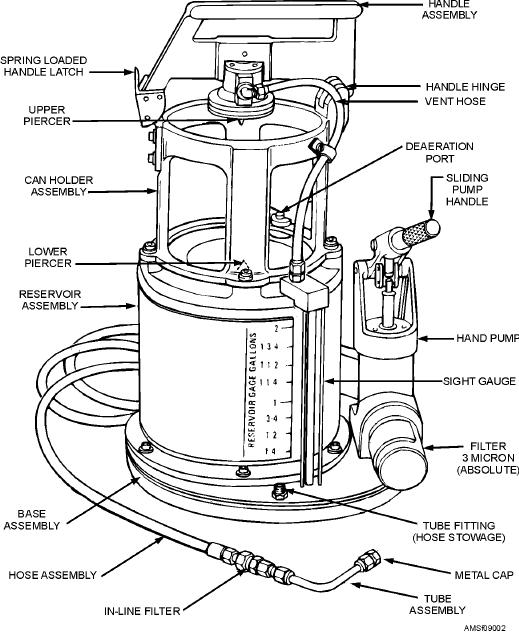

Figure 9-2.--Model HSU-1 fluid service unit.

the hose assembly around the can holder assembly and

to 250 psi. The pump is operated with a sliding pump

fastening the tube end to the hose storage fitting on the

handle, which is held in the extended or retracted

base.

position by a spring-loaded ball detent. A replaceable

3-micron (absolute) disposable filter on the pump base

Model 310 Fluid Service Cart

removes particulate contamination from the hydraulic

fluid being delivered to the suction side of the pump.

The Model 310 fluid service cart (fig. 9-3) is a

The filter unseats a shutoff valve, which closes the

hand-propelled, mobile unit designed to service

suction port whenever the filter element is being

aircraft hydraulic systems with fluid obtained directly

replaced.

from the 10-gallon container. It can be operated by one

person, and it is used in those applications where the

The HSU-1 service unit is equipped with a 7-foot

fluid capacity of the H-250-1 servicing unit (1 gallon)

service hose connected to the unit's fluid output port at

or HSU-1 servicing unit (3 gallons) is inadequate. The

the pump assembly. The hose assembly ends with a

hand pump is used to deliver 3-micron (absolute)

short bent-tube assembly for direct connection to fill

filtered fluid.

fittings on the aircraft or components being serviced.

A 3-micron, in-line filter is located between the hose

The main frame assembly of the fluid service cart

end and the tube. This prevents reverse-flow

consists of a two-wheel dolly having a tubular handle

contamination and serves as a final filter. When the

extending outward so you can hand push (or pull) the

fluid service unit is not in use, it is stored by wrapping

cart. The frame contains an inner bridle, which, with

9-3