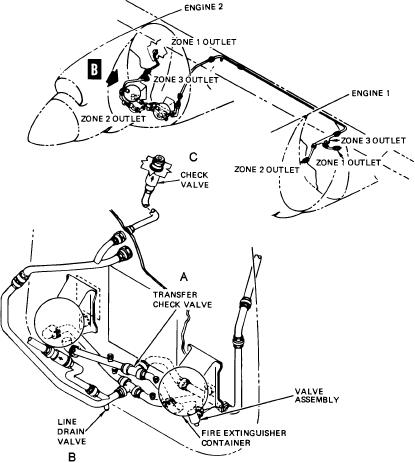

Drain Valves

no. 1 and no. 2 engine nacelles) or no. 2 (right wing, no.

3 and no. 4 engine nacelles). Each system has only two

Drain valves (fig. 5-23, item B) are provided in the

containers; one container for each engine or two

plumbing immediately forward and aft of each transfer

containers for the same engine. Either system is no

check valve, and when the tubing is routed from an

longer effective for fire extinguishing after the two

inboard engine to the wing front beam. A drain valve

containers in the system have been discharged. The two

constructed in the same manner as a check valve is

main plumbing lines from each container for a system

spring-loaded to the open position to drain any

are connected to transfer check valves and then to

condensation at the low points in the system plumbing.

outlets in the engine fire zones. Installed in the

When a container is discharged, pressure of the agent

plumbing between container and transfer check valve is

overcomes the spring force and closes the drain valve,

a test plug.

allowing all agents to go to the engine outlets. As

pressure is relieved in the tubing, the drain valve opens

COMPONENTS

under spring force.

Fire-extinguishing system components include

Check Valve

transfer check valves, drain valves, check valves, and a

container assembly.

Each engine nacelle zone has one

fire-extinguishing outlet. The outlets for zones 1 and 2

Transfer Check Valve

incorporate a check valve (discharge nozzle) (fig. 5-23,

A transfer check valve (fig. 5-23, item A) has two

item C) installed at the end of the plumbing outlet. Zone

inlet ports and one outlet port, and a poppet that shuts

3 has an unrestricted outlet.

off one inlet port. Therefore, only one inlet port is

Container Assembly

utilized for the direct position, and the other inlet port is

used for transfer position. There is no restriction on the

The container (fig. 5-24) is a welded steel sphere

outlet port.

approximately 9 inches in diameter, and is cadmium

Figure 5-23.--Engine fire extinguishing system schematic diagram.

5-20