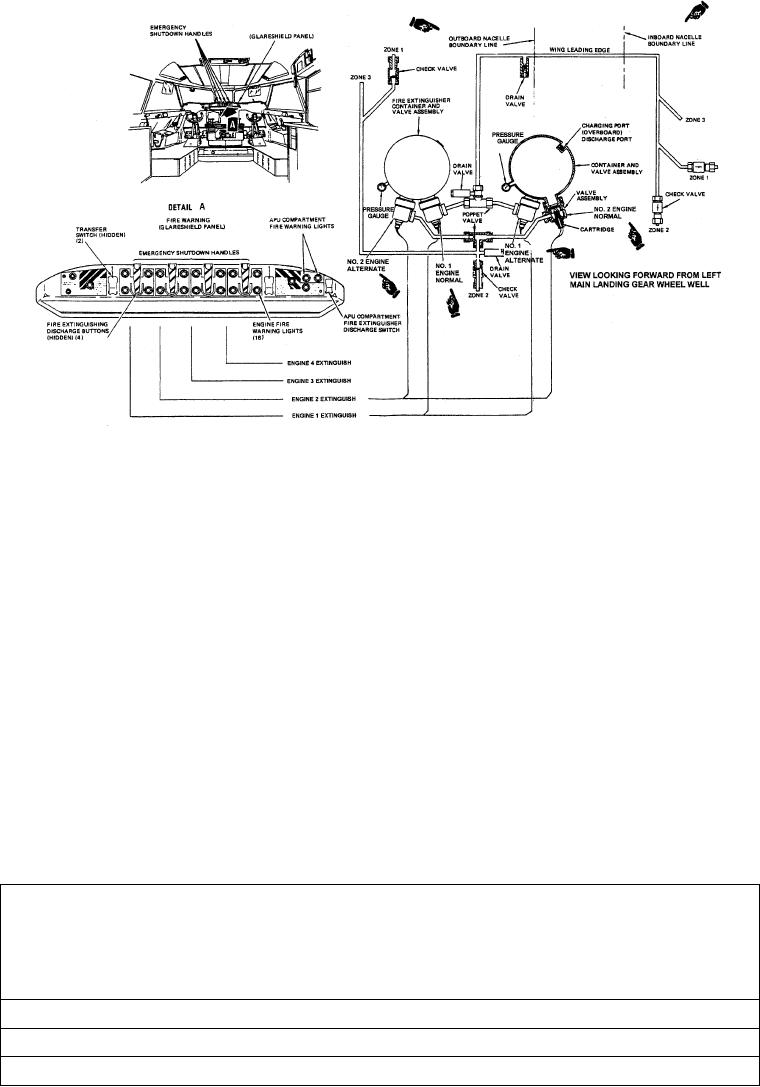

Figure 5-22.--P-3 Engine fire extinguishing system.

CF3BR (the chemical symbol for

equipped with two similar independent electrically

triflourobromomethane) is a fluorinated hydrocarbon.

controlled fire-extinguishing systems, no. 1 and no. 2.

It is the most common extinguishing agent used in

One system is used for fire extinguishing in no. 1 and

aircraft fire-extinguishing systems. It is a more efficient

no. 2 engines and nacelles. The second system is used

extinguishing system than CO2, and under normal atmo-

for no. 3 and no. 4 engines and nacelles. Both systems

are electrically controlled from the flight station.

spheric pressure and temperature, it is an odorless and

Each system utilizes two fire-extinguishing system

tasteless gas. CF3BR exists as a liquid only when contained

container and valve assemblies located in the inboard

under pressure. CF3BR is nontoxic, non-corrosive,

nacelles. The fire-extinguishing system container and

leaves no residue, does not deteriorate with age, is an

valve assemblies are accessible through the main

electrical insulator, and goes farther than CO2.

landing gear wheel wells and an access door on the

NOTE: CF3BR is very volatile. It is nontoxic,

power plant firewall. A pressure gage mounted on each

but a danger of suffocation exists because, like

container is visible under a hinged access door on the

carbon dioxide, CF3BR replaces oxygen when

firewall. Each container is pressurized to 600 (+25, 0)

breathed. Among the many fire-extinguishing

psi and charged with 10.5 (+25, 0) pounds of

agents, only CF3BR will be discussed in this

fire-extinguishing agent. A chart with a minimum

chapter. The P-3 aircraft uses a typical CF3BR

pressure versus container temperature curve is shown

fire-extinguishing system.

in table 5-1.

The P-3 fire-extinguishing system (fig. 5-22)

There are no plumbing interconnections between

controls fires within the engines and nacelles and is

the two fire-extinguishing systems, no. 1 (left wing,

Table 5-1.--Engine and APU Fire Extinguisher Container and Valve Assembly Minimum Pressure Versus Temperature

NOTE

Pressures listed are minimum for known temperature of container to ensure proper operation of the system. Ambient

temperature may be used to determine container temperature, if at least 4 hours have elapsed since last engine

operation. If pressure gauge reads in excess of 100 psig above minimum, container must be removed not later than

next phased inspection. A pressure reading of 50 psig maximum below chart pressure is acceptable for container use.

CONTAINER TEMPERATURE

C

51

40

29

18

7

1

5

10

16

21

27

32

38

43

49

51

60

65

F

60

40

20

0

20

30

40

50

60

70

80

90

100

110

120

130

140

150

5-19