There are eight circuit breakers used in the engine

fire-extinguishing system. These circuit breakers are

located at the forward load center and supply 28 Vdc,

when a closed electrical path has been provided

through the discharge switch to ignite the cartridges in

the fire-extinguishing container and valve assembly.

Four emergency shutdown handles and four

fire-extinguishing discharge switches arm and dis-

charge the system. Normally, a discharge switch is not

actuated until the respective emergency shutdown

handle for that engine has been pulled aft. A protective

guard around the switch prevents inadvertent actuation

of the discharge button although the switch can be

pushed. With an engine fire indicated by the fire

warning lights on the fire-extinguishing control panel,

the respective and individual emergency engine

shutdown handle is pulled aft approximately 6 inches to

gain access to the discharge switch for the engine

nacelle indicating the fire.

As a specific example, if a fire is indicated in no. 3

engine nacelle, pull no. 3 engine emergency handle aft

and press the no. 3 engine fire-extinguishing discharge

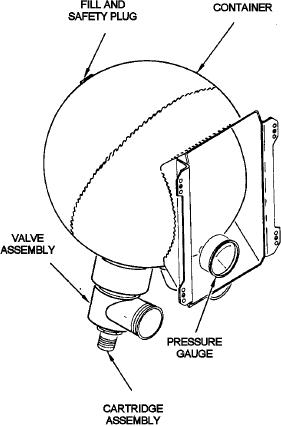

Figure 5-24.--Fire extinguishing system container and valve

button. If the fire persists and it becomes necessary

assembly.

to discharge the second container of the same

fire-extinguishing system into no. 3 engine nacelle, the

transfer switch, which is guarded and shear-wired in the

plated for corrosion prevention. The internal volume of

DIRECT TO ENGINES position, must be set to

the container is 400 (+20, -15) cubic inches. The

TRANSFER TO ADJACENT ENGINES, and the no. 3

container is filled with 10.5 (+0.25, -0.00) pounds of

engine fire-extinguishing discharge button must be

fire-extinguishing agent and pressurized with nitrogen

pressed again. This action electrically ignites the

to 600 (+25, -0) psi. Total weight of the charge is 10.81

cartridge in the transfer container valve assembly of the

to 11.22 pounds including 0.47 pounds of nitrogen. A

second fire-extinguishing container in that system.

mounting bracket, which is welded to the container,

attaches to the forward face of the firewall and

The rate of discharge of a fire-extinguishing system

protrudes through the aft side of the firewall. Each

is approximately 0.4 seconds. All containers, distribu-

container is equipped with two valve assemblies to

tion lines, nozzles, and fittings are of stainless steel.

discharge a container; however, only one assembly is

fired at any one time to discharge a container. Each

AUXILIARY POWER UNIT (APU) FIRE

valve assembly contains a high-temperature

DETECTION AND EXTINGUISHING

electrically controlled dual squib cartridge with a slug

SYSTEM

attached.

The APU compartment fire detection and

OPERATION

extinguishing system provides automatic fire control

on the ground and in flight. The automatic system is

When a fire-extinguishing discharge switch is

backed up by audible and visual warnings and manual

actuated to complete the circuit, the cartridge is

release of the extinguishing agent. The warning light

electrically fired to allow its slug to rupture the

and MAN REL AUX PWR UNIT EXTINGUISHER

frangible disc in the neck of a container. A screen

switch are located adjacent to the no. 4 nacelle

adjacent to the disc retains the six frangible disc

discharge switch on the glareshield APU FIRE

segments when the cartridge is fired. The extinguishing

WARNING AND EXTINGUISHER panel. In addition

agent is expelled from the container. A safety disc plug

to the flight station warning horn, another identical

is installed inside the overboard discharge port and has

horn is located at the main load center, which is

a burst range of 1450 to 1800 psi at 200F.

5-21