are used to balance airflow when the APU/AMP

serves as a single source of air with a flow rate equal to

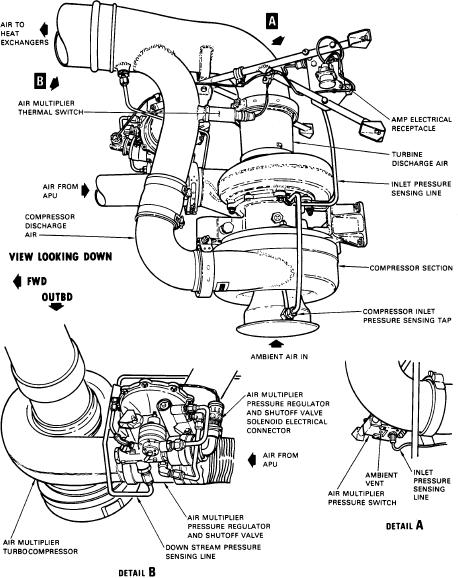

combination is the air supply source. Figure 6-2 shows

that supplied by the two EDCs. With the engines

an AMP installation.

operating at normal revolutions per minute (rpm), each

EDC supplies air to its respective air cycle cooling

COMPONENTS

system at the rate of approximately 60 pounds per

minute (lb/min). The APU/AMP combination supplies

Components include a heat exchanger package,

air to a duct common to both air cycle cooling systems

turbine refrigeration unit, water separator, water spray

at a rate of approximately 125 lb/min. The air volume

system, and a flow-limiting venturi.

divides in the air cycle cooling system interconnection

duct, with half going to the flight station air cycle

Heat Exchanger Package

cooling system and half to the cabin air cycle cooling

system.

The function of the heat exchanger package (fig.

An air-conditioning system that employs a single

6-3) is to reduce the temperature of the supply air

source of air to supply two air cycle cooling systems

furnished by the EDC or AMP. Two heat exchanger

that operate at different back-pressures will have air

packages, each consisting of a primary and secondary

flow problems unless a control is added to balance

section, electric fan assembly, check valve, and ram air

airflow. If airflow is not properly balanced, the air cycle

duct check valve are installed on each side of the nose

cooling system with the lower back-pressure (as the

wheel well. The left heat exchanger package supplies

result of more air bypass) will rob air from the unit with

air for the cabin systems and the right package cools

the higher back-pressure. Two flow-limiting venturis

flight station air.

Figure 6-2.--AMP installation.

6-4