and temperature to the point where the air becomes

aircraft nose wheel well. The refrigeration unit, along

usable for aircraft cooling.

with the secondary section of the heat exchanger,

lowers the temperature of supply air so that it may be

Lubrication of the rotating assembly bearings is

used for aircraft cooling. The refrigeration unit consists

accomplished by an air-oil mist. Oil is absorbed by

of a rotating assembly and a housing assembly. The

wicks, which extend from the oil sump to the shaft of

rotating assembly mounts a turbine scroll and a

the rotating assembly. Oil is distributed on the rotating

compressor scroll, enclosing the rotating assembly. The

assembly shaft as a result of capillary action in the

bottom of the bearing support housing forms a sump for

wicks. Rotation of the shaft causes the oil to diffuse into

lubricating oil. A sight gauge is provided in the sump

an air-oil mist. The action of the oil slingers causes the

for determining the level of lubrication oil. Each of the

air-oil mist to pass through the bearings, providing

three sections formed by the housing assembly is sealed

lubrication.

to prevent air and oil leakage.

Water Separator

Compressed supply air, after it has passed through

the primary section of the heat exchanger, is ducted into

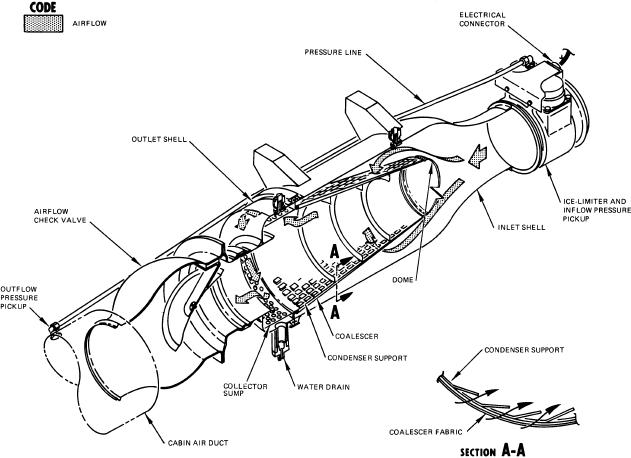

The water separator (fig. 6-5) removes moisture

the compressor section of the turbine where it is further

from the air before it is distributed within the aircraft.

compressed as it passes through the compressor scroll.

Two water separator units are installed in the APU

The compressed air, with a temperature slightly above

compartment. The cabin system unit is located in the aft

that of ambient air, is then routed to the secondary

upper left section of the APU compartment and the

section of the heat exchanger, where it is cooled to a

flight station unit is located in the forward upper right

lower temperature. Returning from the heat exchanger,

section.

the compressed air enters the turbine scroll, expanding

as it flows from the nozzle through the turbine wheel to

The water separator consists of a condenser assem-

the outlet duct. As the air is expanded, it drives the

bly and a collector assembly. The condenser assembly

turbine wheel at high speed. Mechanical energy, which

is a coalescer. An ice-limiting sensor is installed in the

is extracted from the air to drive the turbine wheel, is

inlet section of the unit to protect against icing and a

transmitted to and absorbed by the compressor wheel.

check valve is installed in the water separator outlet to

This mechanical energy reduces the supply air pressure

prevent reverse airflow through the unit.

Figure 6-5.--Dual check valve, water separator, and ice-limiting sensor.

6-6