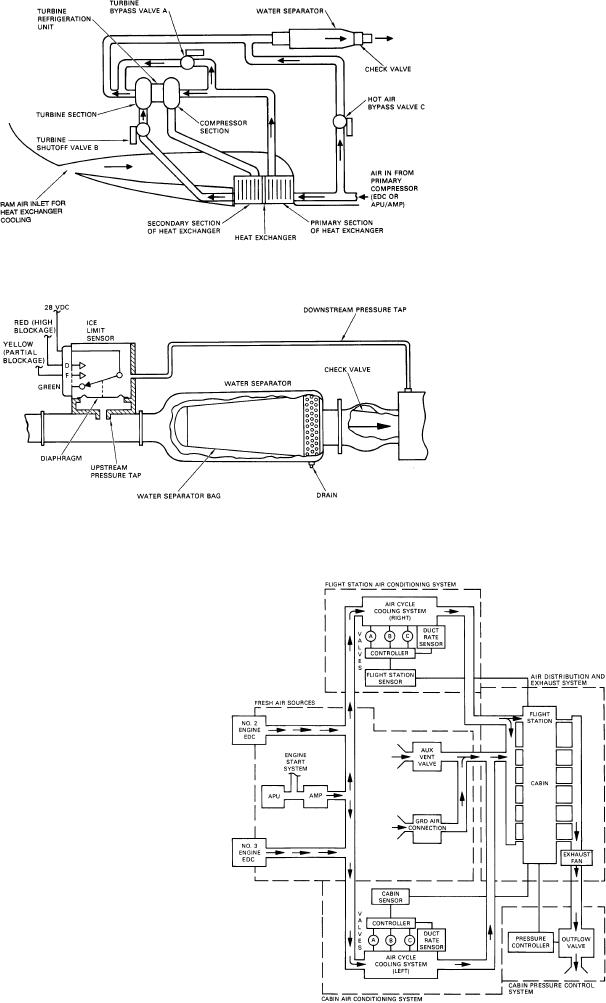

Figure 6-9.--Air cycle cooling schematic diagram.

back-pressure on the air cycle cooling system. High

back-pressure from the air cycle cooling system will

cause the pressure ratio across the EDC to exceed its

design limits and cause a compressor surge condition.

The compressor surge may cause a loss of cooling air at

the dump valve or damage the EDC. The ice limit

sensor, a pressure switch, senses the pressure differen-

tial across the water separator. One side of the pressure

switch senses the air pressure upstream from the water

separator bag, and the other side senses the air pressure

downstream from the water separator bag. When the

bag is covered with ice, the airflow is impeded and a

greater-than-normal pressure drop develops across the

bag. When the pressure differential exceeds 2.9 inches

mercury (Hg), a switch actuates in the ice limit sensor

ice limiter indicating partial blockage (yellow condi-

tion) of the water separator (fig. 6-9). If the water

separator icing condition worsens and the ice limiter

senses an increase in pressure drop across the water

separator bag to 4.1 inches Hg, the high-pressure switch

actuates in the ice limit sensor, indicating heavy block-

age (red condition) of the water separator. These ice

limiting sensor signals are used by the temperature con-

trol system, during the automatic mode only, to control

water during icing. Figure 6-10 shows the ECS flow.

Figure 6-10.--ECS block diagram.

6-11