compartment in the air distribution duct between the

As supply air passes through the coalescer,

AMP and the EDC air ducts. The venturi is sized to

moisture particles are condensed into droplets. After

limit airflow to 67 lb/min from the AMP to the air cycle

the air has passed through the coalescer, hundreds of

cooling system to ensure proper flow division and to

small vanes create a swirling motion of the air and the

prevent excessive flow through the aircraft during the

airborne water droplets. This swirling motion

heating mode. It functions to limit flow through the

centrifuges most of the water droplets from the air into

refrigeration unit in the event the other refrigeration

the coalescer sump, where the water accumulates and

unit is operating at a different bypass setting; that is,

drains overboard. The air, relieved of approximately 70

one refrigeration unit is in maximum cooling while the

percent of its moisture, is then ducted into the aircraft

other is modulated toward heating. A check valve is

and distributed.

located in the outlet of each venturi to prevent reverse

Water Spray System

EDC airflow through the venturi.

The water spray system increases basic cooling

CABIN AND FLIGHT STATION

capacity of the air cycle cooling system by spraying

TEMPERATURE CONTROL SYSTEM

water separator discharge water into the ram air,

cooling it by evaporation before the ram air passes

There are two independent temperature control

through the heat exchanger's secondary section.

systems on the aircraft designed to control the

temperature of the air cycle cooling system output

Flow-Limiting Venturi

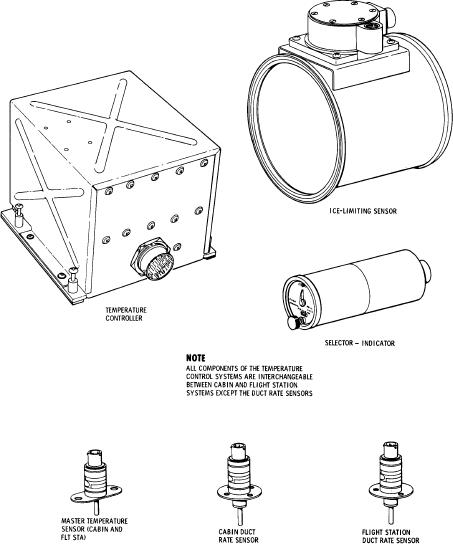

air. Each system (fig. 6-6) is composed of a

Each air cycle cooling system has a flow-limiting

selector-indicator, a temperature controller, a master

venturi installed in the left and right sides of the APU

temperature sensor, a duct rate sensor, an ice-limiting

Figure 6-6.--Temperature control system components.

6-7