is able to initiate command-sequenced ejec-

of surface contact, the occupant has oxygen from a

tion?

system in the survival kit. At an altitude between

14,500 and 11,500 feet, the barostat assembly releases

Q1-8. During ejections below 13,000 1,500 feet,

the time-release mechanism escapement, initiating its

what assembly will actuate at approximately

timed operation. Upon actuation of the time-release

0.5 second after ejection?

mechanism, occupant release and separation occurs the

Q1-9. What procedure must be initiated if the

same way as ejection sequence below 13,000 1,500

time-release mechanism fails?

feet.

EJECTION SEQUENCE FOR MANUAL

COMPONENTS

SEPARATION

LEARNING OBJECTIVE: Identify the ma-

If the time-release mechanism fails, or if the terrain

jor ejection seat components.

altitude is above the setting of the barostat, the occupant

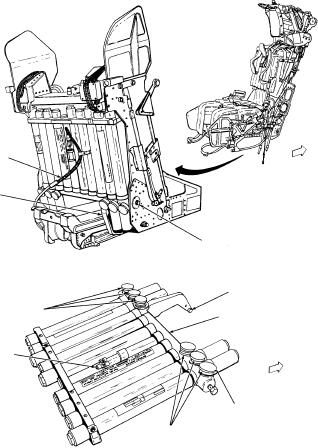

The components discussed below include the

must initiate manual separation from the seat and

rocket motor (DODIC M938, M939, and M940), rocket

deployment of the personnel parachute. The following

motor initiator, color-coded brackets, main beam as-

will occur:

sembly, top latch mechanism, time-release mechanism,

1. The occupant puts the emergency restraint

personnel parachute, upper restraint harness, and

release in its full up unlock position, releasing

parachute harness sensing-release units.

the upper harness locks, personnel parachute

restraint locks, survival kit to seat lock, and

ROCKET MOTOR (DODIC M938,

leg-restraint line locks. This action reduces

M939, AND M940)

sticker clip tension and fires the guillotine

cartridge.

Each Martin-Baker MK GRUA-7 ejection seat has

2. The gas from the cartridge operates the

a rocket motor attached to the underside of the seat

guillotine unit to sever the personnel parachute

bucket (fig. 1-3). The rocket motor is connected by a

withdrawal line.

3. The occupant must now rotate forward and

push the seat bucket with his hands to separate

from the seat.

4. When free of the seat, the occupant must pull

the personnel parachute manual release (para-

chute ripcord handle) to deploy the personnel

parachute.

AFT

SEPARATION OF PARACHUTE FROM

FLEXIBLE GAS HOSE

CREWMEMBERS

CAM FOLLOWER

ENGAGED IN

INCLINED TRACK

Manually opening the canopy release assembly is

the primary means of separating the parachute from the

ATTACHMENT BOLT

crewmember. The SEAWARS (a backup mode) auto-

VIEW LOOKING UP

matically releases the parachute from the crewmember

within two seconds after seawater entry. When the

CAM FOLLOWER

parachute harness sensing release units are immersed in

NOZZLES

CENTER BODY

seawater, cartridges fire to separate the parachute risers

from the canopy release assembly. Immersion in fresh

GAS OPERATED

IGNITER UNIT

water will not activate the parachute harness sensing

AFT

release units.

DUST CAP

TYPICAL

Q1-6. During command sequenced ejection, the

6 PLACES

NOZZLES

sequence gas generator sear is extracted by

rotation of what assembly?

ROCKET MOTOR

(BOTTOM VIEW)

Q1-7. With the CMD EJECT SELECT handle in the

AMEf0103

ECMO command position, what crewmember

Figure 1-3.--Rocket motor (DODIC M938, M939, and M940).

1-7