Each injector is fitted into a water-cooled copper

tube in the cylinder head and is held in place by an

injector clamp. It is operated by a push rod and rocker

arm. As the rocker arm forces the plunger down, the

upper helix closes the upper port, and fuel injection

begins. The upper helix and a lower helix are machined

TIMING

into the lower end of the plunger for metering purposes.

DIMENSION

The relation of these helices to the ports changes with

the rotation of the plunger. As the plunger moves

4

downward, a portion of the fuel trapped in the bushing

6

under the plunger is displaced through the lower port

back into the supply chamber, until the port is closed off

1

by the lower end of the plunger. A portion of the fuel

still trapped under the plunger is then forced upward

through the central passage of the plunger into the

recess between the two helices, and then into the supply

5

chamber through the upper port, until the upper helix

closes that port. With the upper and lower ports closed,

3

2

the remaining fuel trapped under the plunger is

subjected to increased pressure by the continued

downward movement of the plunger. When sufficient

pressure is built up, the injector valve is lifted off its seat

and the fuel is forced through small orifices in the spray

ASf04048

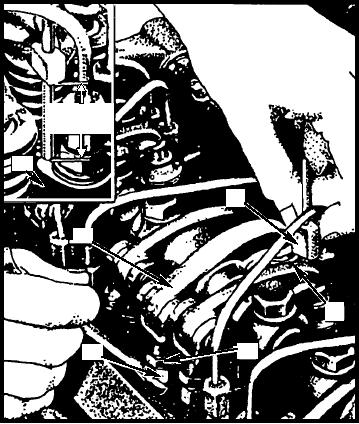

1. Rocker injector arm

4. Fuel injector

tip and atomized into the combustion chamber. The

2. Push rod

5. Injector follower

rotation of the plunger, by moving the rack, changes the

3. Locknut

6. Injector timing gauge

position of the helices and retards or advances the

closing of the ports and the beginning and ending of the

Figure 4-48.--Timing fuel injectors.

injection period. Fuel injection ends when the lower

helix opens the lower port. The remaining fuel then

case of 2-stroke cycle engines, are placed in the air

proceeds through the upper manifold, or outlet, back

passages surrounding the cylinders. The preheater

into the tank.

burns a small quantity of diesel fuel in the air prior to

the air being drawn into the cylinders. This burning

To properly time an injector, adjust the injector

process is accomplished by the use of either a glow plug

follower to a definite height in relation to the injector

or an ignition coil, which produces a spark to ignite a

body (fig. 4-48). This will vary according to the size of

fine spray of diesel fuel. The resulting heat warms the

the injector being used. Check the manufacturer's

remaining air before it is drawn into the cylinders.

manual to determine the proper gauge to use.

Glow Plugs

COLD WEATHER STARTING DEVICES

Glow plugs (fig. 4-49) are installed directly in the

Diesel fuel evaporates much slower than gasoline

precombustion or turbulence chamber of the cylinder

and requires more heat to cause combustion in the

head. The injection nozzle is also in this chamber.

engine's cylinders. For this reason, preheating devices

When you crank the engine, the glow plug is turned on.

and starting aids are found on all Navy equipment using

The heat created by electrical resistance in the glow

diesel engines. These devices and starting aids either

plug heats the fuel and air mixture. Heat generated by

heat the air before it is drawn into the cylinder or allow

the glow plug permits burning of the fuel in the

combustion at a lower temperature than during normal

chamber and cylinder.

engine operation.

Starting Fluid

Preheaters

Starting fluid, in either an aerosol container or

Preheaters, the most common type of heating

capsule, is frequently used as a starting aid. This fluid is

device, are installed in the intake manifold or, in the

a highly volatile fluid (ether or a suitable substitute),

4-36